Carbon nanotubes have attracted lots of attention from various fields of scientists because they exhibited extraordinary physical and chemical properties due to their intrinsic nanosized one-dimensional nature[1]. Thus, their intrinsic characteristics will make revolutionize everything from computer, bio- and medical-device, batteries, nanocomposite-based vehicles to electronic nano-device etc in the near future[2]. Up to now, much effort has been paid on the establishment of the cost-effective synthetic techniques for producing carbon nanotubes in a large scale. Noticeably, a floating reactant method based on the catalytic chemical vapor deposition (CVD) method enabled us to produce multi-walled carbon nanotubes in a large quantity at a relatively low cost[3,4]. Therefore, a synergistic effect of an industrially produced carbon nanotubes and the newly created end-uses will cut down their price by at least 10 percent of the current value in the near future. At present, the biggest obstacle for blocking widespread applications of carbon nanotubes is considered to be the safety issue[5]. Thus, it is now urgently needed to clarify their potential toxic nature on human health and environment with detailed and systematic studies of toxicological evidences of carbon nanotubes, because what we worry the most is the misunderstanding among the general public, which might lead to the reluctance to use these tiny materials.

In this account, we, first, describe the bulk synthesis of high-purity carbon nanotubes based on the floating reactant method, and then their current usages in the range from multifunctional filler in various matrices as well as in electrochemical systems will be discussed with a detailed study of the effect of nanotubes texture and morphology. Finally, I will clarify the potential toxic of carbon nanotubes through the systemic study of various carbon nanotubes because the controlled safety of carbon nanotubes is critical for successful business.

2. How Carbon Nanotubes Produced in Industrial Scale

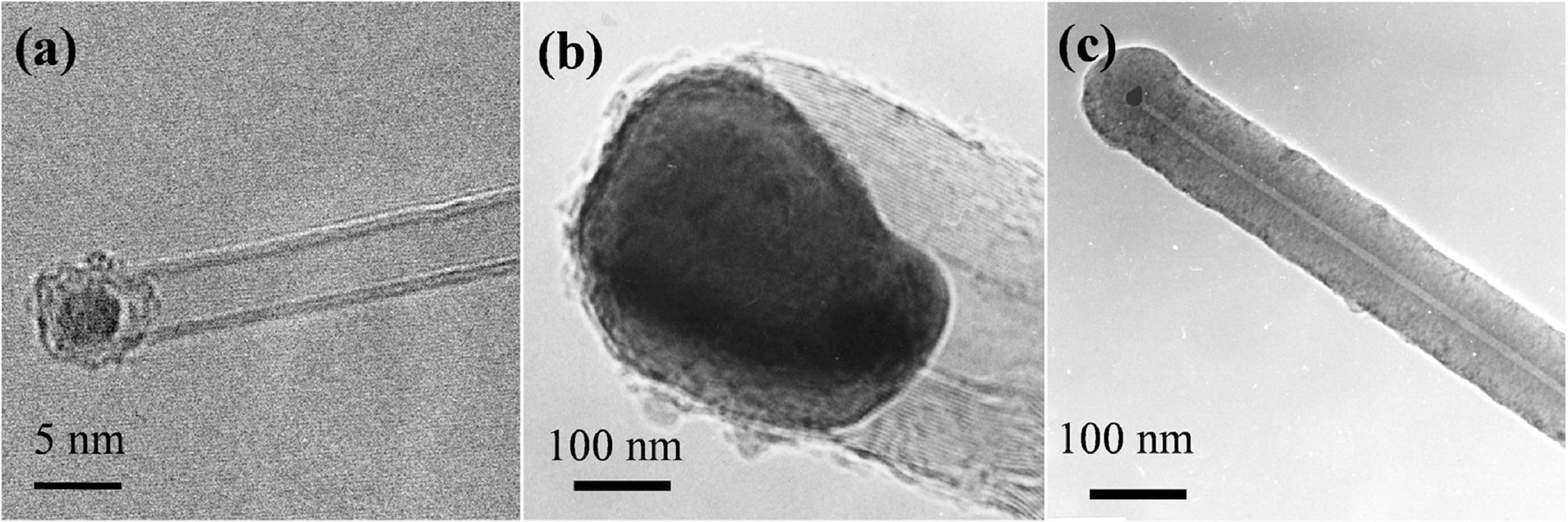

Up to now, various synthetic methods for producing carbon nanotubes have been reported (e.g., arc discharge, laser vaporization and CVD). The dominant recent trend is to synthesize carbon nanotubes using a CVD method because this technique is very powerful tool for the largescale production of both single- and multi-walled carbon nanotubes (SWNTs and MWNTs, respectively) especially using a floating reactant technique[3]. By simultaneously feeding hydrocarbons and nanoscale catalytic particles (or precursor) such as iron in the gas phase into reaction chamber (micro-sprayer or vapor), carbon nanotubes have been synthesized in a large-scale. Growth of SWNTs and MWNTs in reactor has been proposed to involve the catalytic deposition of hydrocarbons over the surface of nano-sized metal particles and a continuous output by the particle of well-organized tubule of hexagonal sp2-carbon, with extraordinary growing speed. The strong evidence of this assumption is the presence of catalytic particles at the ends (top or root) of the tubes (see Fig. 1 (a-c))[1].

Regarding the bulk production of MWNTs for industrial applications, Showa-Denko Co. Ltd and Hyperion Catalysis

International, Inc. commenced to produce several tons of catalytically grown carbon nanotubes annually. In particular, high-purity MWNTs (ca. 100 ton/year) have been used as multifunctional filler in the anode of the lithium ion secondary batteries[4]. Very recently, Showa Denko has announced to increase the production capacity up to 400 tons/year in 2009[6]. The most interesting point is that all companies selected a catalytic CVD method based on iron catalysis, and furthermore all companies adopted the floating reactant technique for the large-scale production of MWNTs. Even though a great deal of progress has been achieved related to the bulk synthesis of carbon nanotubes, carbon nanotubes are still expensive. However, a synergistic effect of large-scale production, and also newly developed end-use (e.g., nanocomposite) will cut down price by at least 10 percent of the current value.

3. Multi-functional Filler in Nanocomposites

It has been shown that carbon nanotubes could behave as the ultimate one-dimensional material with remarkable mech-anical properties. Moreover, carbon nanotubes exhibit enhanced electrical and thermal conducting properties; better than those of copper. Therefore, carbon nanotubes have been studied intensively as fillers in various matrices, especially polymers[2]. The best utilization of the intrinsic properties of these fibrous nanocarbons in polymers could be achieved by optimizing the interface interaction of the nanotube surface and the polymer. Therefore, surface treatments via oxidation in conjunction with the polymer or epoxy could be used in order to improve adhesion properties between the filler and the matrix. This results in a good stress transfer from the polymer to the nanotube. Very recently, we have developed a super rubber sealant that is able to withstand temperatures up to 260℃ and pressures as high as 239 MPa by incorporating surface-modified MWNTs into fluorine rubber[7]. Thus our rubber sealant will contribute to a revolutionary enhancement in the oil recovery efficiency from the current 35%to more than 70% by excavating previously inaccessible deposits.

4. Carbon Nanotube Biocompatibility

Much attention was paid on the toxicity of carbon nanotubes due to their nanoscale dimension and also similar morphological features to that of asbestos. Up to now, there have been limited reports related to the potential toxic nature of carbon nanotubes. Thus, the toxicological evidences of carbon nanotubes are strongly requested for preventing a risk of occupational disorders in workers and promoting their applications in various consumer uses. Recently, we have suggested simple and effective method to evaluate the toxicity and biocompatibility of carbon nanotubes through a measurement of CD4+ and CD8+ T-cells in peripheral blood[8,9]. Their histopathological study on carbon nanotubeimplanted tissues because CD4+ (a co-receptor for MHCII) and CD8+ (a co-receptor for MHCI) give us important antigen information of T cells. Interestingly, in our protocol demonstrated here, a mortality of animals was as small as almost inert and no chronological changes of body weight were observed among nanotubes-implanted mice versus control over 3 months post-implantation. Time-dependent changes in peripheral T-cells, which involved into carbon nanotubes in situ, were well correlated with a processing phase of granuloma formation. In contrast, our previous study on the biological response of asbestos revealed a distinctively low value of CD4+/CD8+ and severe inflammatory aspects with giant cells after subcutaneously asbestosimplantation for one month in mice. Our preliminary studies on the biological response of carbon nanotubes revealed that their potential toxic nature is significantly low (inert). However,more detailed and systematic (long-term) studies with regard to the toxic natures of various types of carbon nanotubes including direct aspiration of the tubes in lung have to be carried out to strongly appeal the safety nature of carbon nanotubes.

These tiny, black and tubular-type nanomaterials, having from single to multi shell structure, will revolutionize everything from computer, bio- and medical-device, nanocomposite-based vehicles to electronic nano-device, whereby their related products will ultimately change the way we live, work and communicate. It should be noted that lots of carbon nanotubederived products are already in use and their viability strongly depend on their commercialization.

To achieve the success story of carbon nanotubes, at least four obstacles have to be solved. First is how to obtain high purity carbon nanotubes because the remained metallic impurities were known to give rise to toxic properties

[Fig. 2.] A schematic image describing four mountains to be solved for successful nanotube business.

Second is how to manipulate these tiny materials what we want (e.g., electronics). Thirdly, the most tremendous job is how to control the chirality of carbon nanotube. Finally, the most important but critical “safety” issue has to be clarified based on long-term and systematic biological studies.

We have proceeded beyond the first mountain of science, the second mountain of technology and the third mountain of economy by successful large-scale production of carbon nanotubes at a reasonable cost (Fig. 2). Now we are striving to climb the mountain of society. By sharing the all information on risks and benefits of the materials with all stakeholders, we will finally reach the top of a nanotube mountain and prove the carbon nanotubes to be the innovative materials in the 21st century.