Carbon nanotubes (CNTs) have generated great interest from both fundamental and practical points of view, and they have been proposed for many potential applications [1-4], such as sensors [5,6], field-emission devices [7,8], logic devices [9,10], and probes in various chemistry and biology [11,12]. Especially, development of the polymer/CNTs composites has been widely studied because of its superior mechanical and electrical properties [13,14]. Several studies have been devoted to the uses of CNTs as fillers to improve performances of composites or to achieve new properties of the composites, due to the superior Young’s modulus (up to 1 TPa) [13], large aspect ratio, and high electrical conductivity (up to 103 S/cm) [14] of CNTs.

Among the most versatile polymer matrices, poly olefins, such as polypropylene (PP) are thermoplastics having a higher consumption because of their well-balanced physical and mechanical properties and their easy process ability at a relatively low cost. Mechanical properties of PP are generally modified by melt mixing with particulate (

However, the effective use of CNTs as fillers in polymer composites depends on the capacity to obtain a good dispersion of CNTs in the matrix, without damaging them or reducing their aspect ratio. Techniques such as end-group functionalization, use of ionic surfactants, shear mixing, and plasma coating have been used to improve dispersion and exfoliation of nanotubes in polymers. Polypropylene compatibility with fillers has been improved by matrix modification by grafting it with reactive moieties, such as acrylic acid, acrylic esters, and maleic anhydride [13]. Improvement in thermal and electrical properties of PP/CNT composites has been reported [14].

In this work, multi-walled carbon nanotubes were treated using glycidyl methacrylate by chemical modification and the effect of GMA-grafting on the MWCNT surfaces in the GMA-MWCNT/PP nanocomposites for viscoelastic behaviors was investigated.

MWCNTs used in this study were synthesized by chemical vapor deposition and provided by Nanosolutions Co. The diameter was 10~25 nm with micrometer length, and the purity was >95 wt%. The MWCNTs were used in our experiment with further purification. Hydrochloric acid (35%) was obtained from Burdick and Jackson. Hydrogenperoxide (38%) from Sanchun chemical Co., Ltd. was used for efficient grafting of hydroxyl group. Glycidyl methacrylate (GMA, purity 97%) and 3-Chlorotoluene (98%) were purchased from Sigma-Aldrich.

2.2. Preparation of GMA-MWCNTs/PP nanocomposites

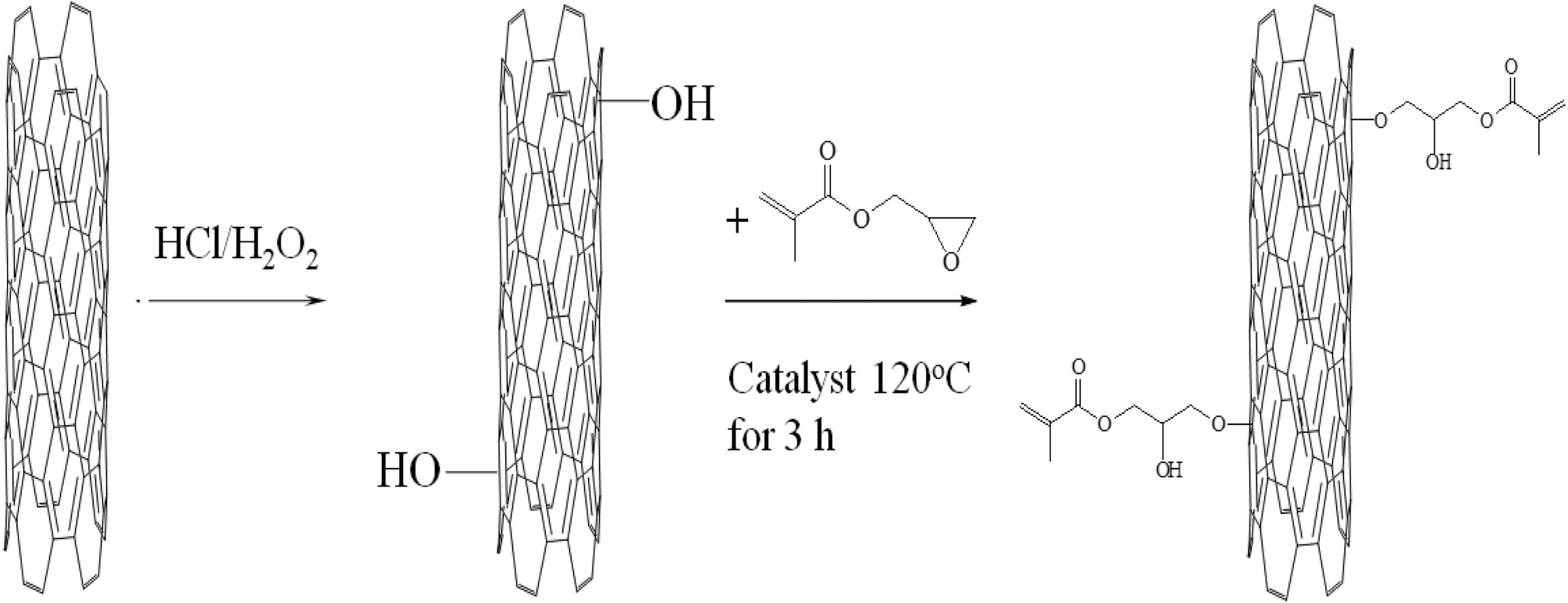

The MWCNTs (1 g) were pretreated with HCl (35%) at room temperature for 5 h. And then, MWCNTs were added in H2O2(38%) and stirred about 12 h at 80℃. Acid-modified MWCNTs were washed with distilled water for neutralization. After vacuum filtration with micro-sized polycarbonate membrane, it again dried for 12 h at 80℃ in a vacuum oven [15].

Finally treated MWCNTs (0.5 g) and GMA (35 g) were mixed in the 100 mL beaker with the homogenizer for 30 min. The suspended substances were poured into flask. The flask was located in an oil bath at 120℃. 3 mg of 3-chlorotoluene as a catalyst was added into the flask, and the mixture was stirred for 3 h at 120℃. And then, the GMA-MWCNT mixture was diluted with CHCl3 and vacuum filtered. The filtered GMA-MWCNTs were thoroughly washed with CHCl3, and then filtered and dried overnight under vacuum at 80℃ [16]. The scheme for GMA-MWCNTs was presented in Fig. 1.

Typically, the GMA-MWCNTs/PP nanocomposites were prepared by melt mixing in bravender (30 rpm) at 200℃ for 1 h. To prepare samples for measuring the viscoelastic behaviors, finally obtained GMA-MWCNTs/PP nanocomposites were transformed to film form which has thickness of 1 mm and diameter of 25 mm by using hot press [17].

2.3. Measurements and characterization

The structural properties of pristine MWCNTs and GMAMWCNTs were investigated by FT-Raman measurements (RFS 100/S: Bruker, FT-Raman). The amount of grafted GMA was calculated by thermogravimetric analysis (STA 409 PC:NETZSCH, TGA). And the FT-IR (FT/IR-6100: JASCO) was used for the investigation of GMA-MWCNTs. The dispersion of GMA-MWCNTs in PP was analyzied using SEM (S-4200:HITACHI). And the viscoelastic properties were carried out using rheometer system (AR 2000ex: TA Instruments, Ltd, Rheometer) by frequency sweep procedure from 0.1 to 100 rad/s and using period of shear rate from 0.1 to 10 s-1 at 200℃.

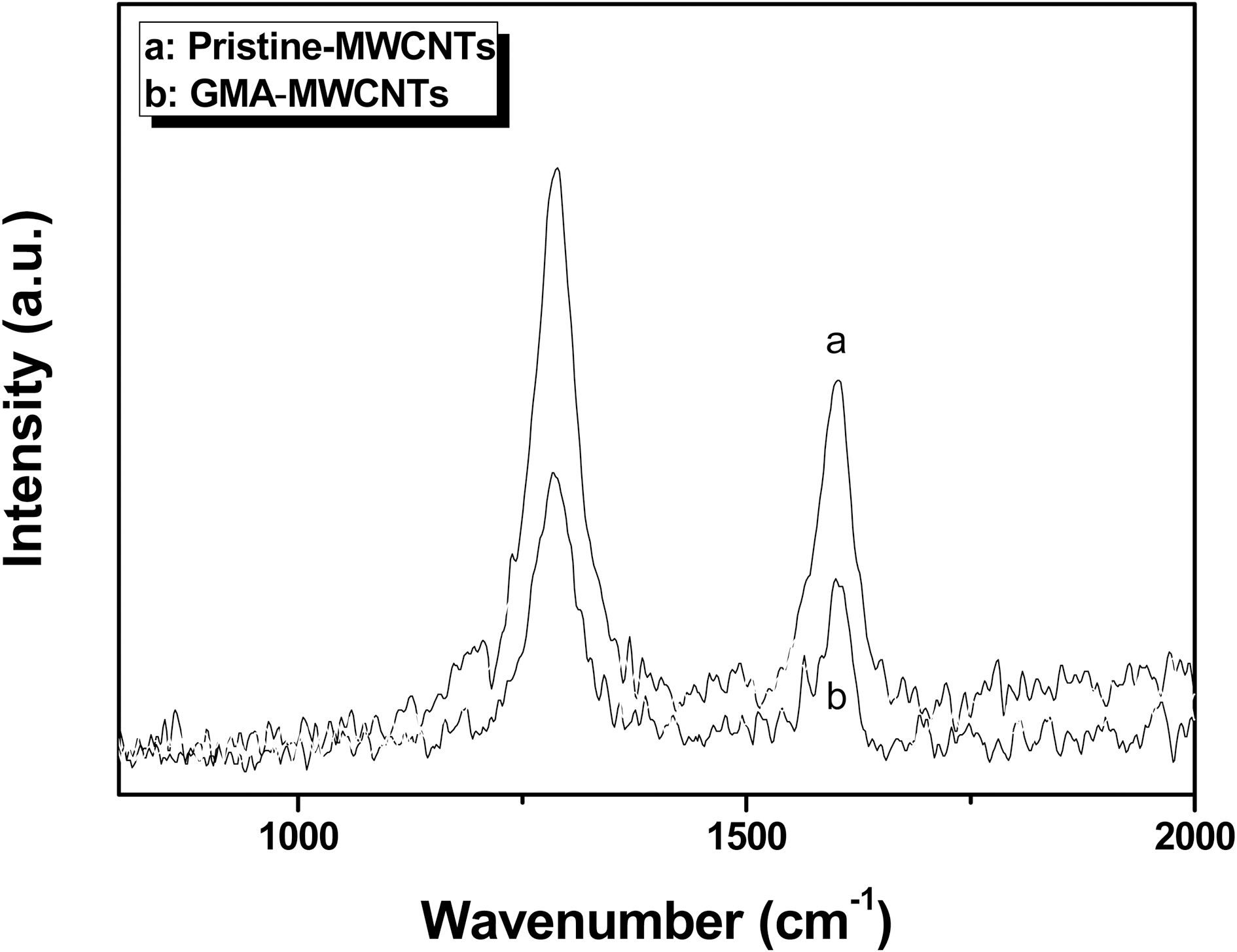

FT-Raman was used to investigate surface features of

GMA-MWCNTs. The Raman spectra normally use to carry out surface characteristics and structural properties of carbon based materials. Fig. 2 describes D band (defect or disorder mode) and G band (graphite or tangential mode) of FT-Raman spectra for MWCNTs and GMA-MWCNTs. The D band is describing defect elements of MWCNTs. It was found regularly in the range of 1330~1360 cm-1. On the other hand, the G band meant flexible mode which was appeared from graphitic plane and matched with tangential shear of carbon atom. The G band was shown at 1580 cm-1 [16].

For all regions in the graph, the peak placements of D band and G band were not significantly changed after GMA grafting, but the peak intensity and area were slightly decreased. In this situation, it was considered that GMA was grafted on the surface of MWCNTs. In the intensity ratio of D band and G band (ID/IG ratio), ID/IG value (1.64) of GMA-MWCNTs was higher than that of pristine MWCNTs (1.56). It was considered that relative increase of ID/IG value was caused by partly increment of structural amorphous surface of GMA-MWCNTs [17,18].

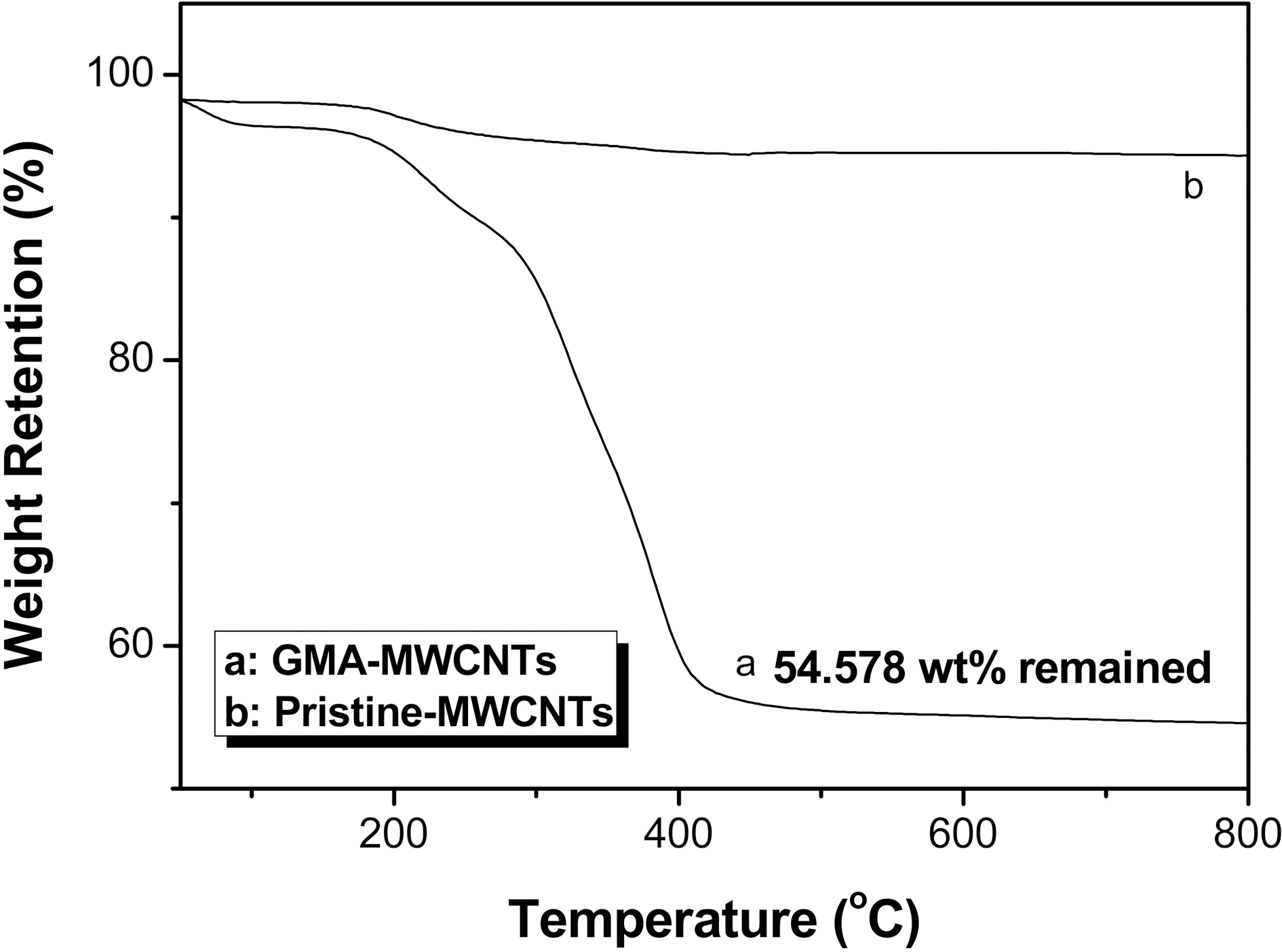

To calculate GMA mass which was grafted on the surface of MWCNTs, TGA was used. Prepared pristine MWCNTs and GMA-MWCNTs were measured from room temperature to 800℃ in N2 atmosphere. As shown in Fig. 3, pristine MWCNTs showed 15 wt% decreases. On the other hand, GMA-MWCNTs was remarked about 45 wt% mass loss started from 200℃, continued rapidly nearby 300℃ and after 650℃ it was remained about 55 wt%. For these reasons, it was concluded the GMA was grafted with 45 wt% mass ratio on the MWCNT surfaces [19].

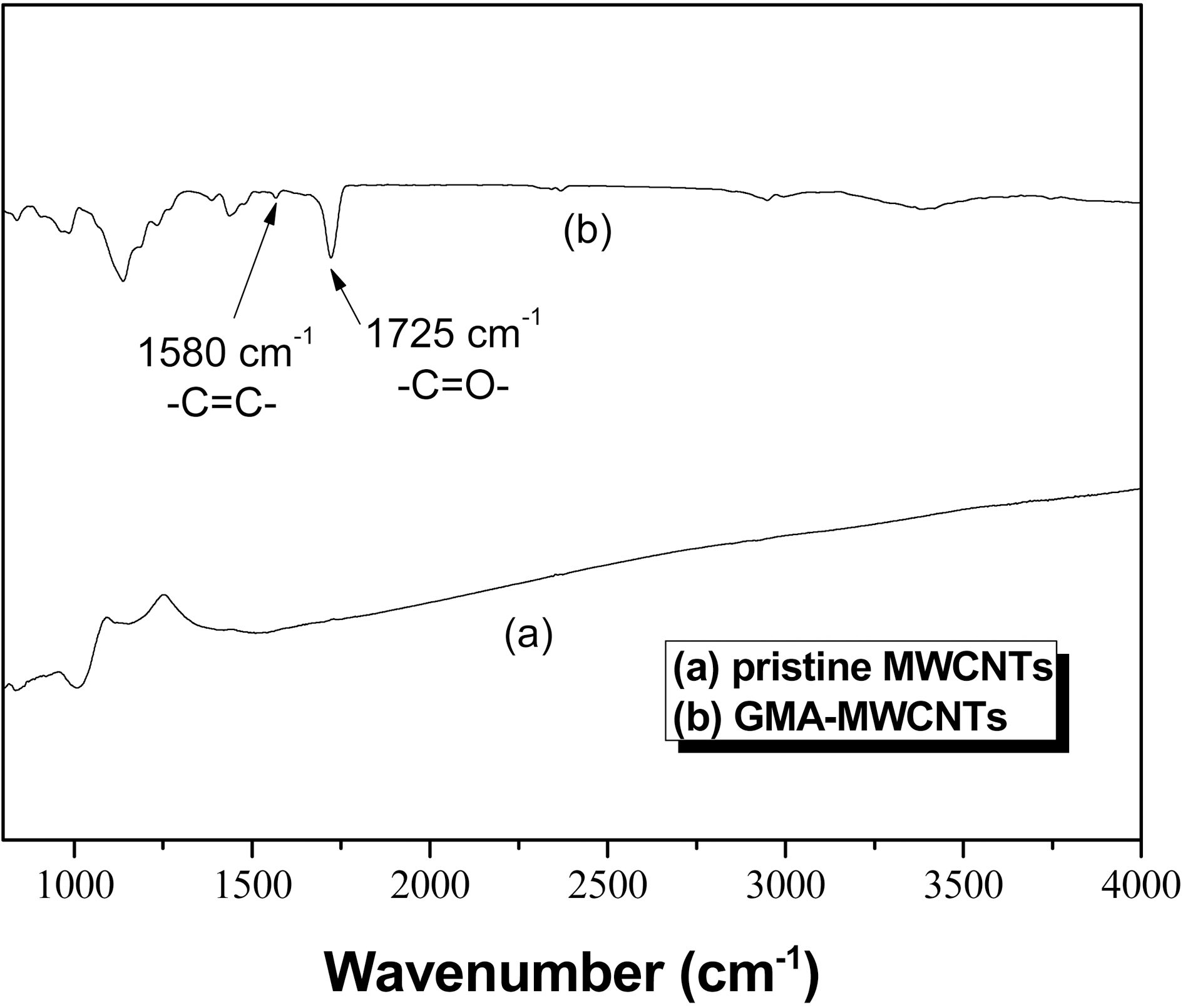

Fig. 4 shows the FT-IR spectra of (a) pristine MWCNTs and (b) GMA-MWCNTs. In pristine MWCNTs, there are no measurable functional groups. On the other hand, after functionalization, GMA-MWCNTs show a band at 3400 cm-1 which is attributed to the -OH stretching vibrations by the

grafting of GMA onto MWCNTs. And a band of 1725 cm-1 indicates to the ?C=O stretching vibration of GMA-MWCNTs. In addition, GMA-MWCNTs exhibits a band at 1580 cm-1 attributed to C=C double bond. From above results, GMA had covalently bonded on the surface of MWCNTs through ring-opening reaction [16].

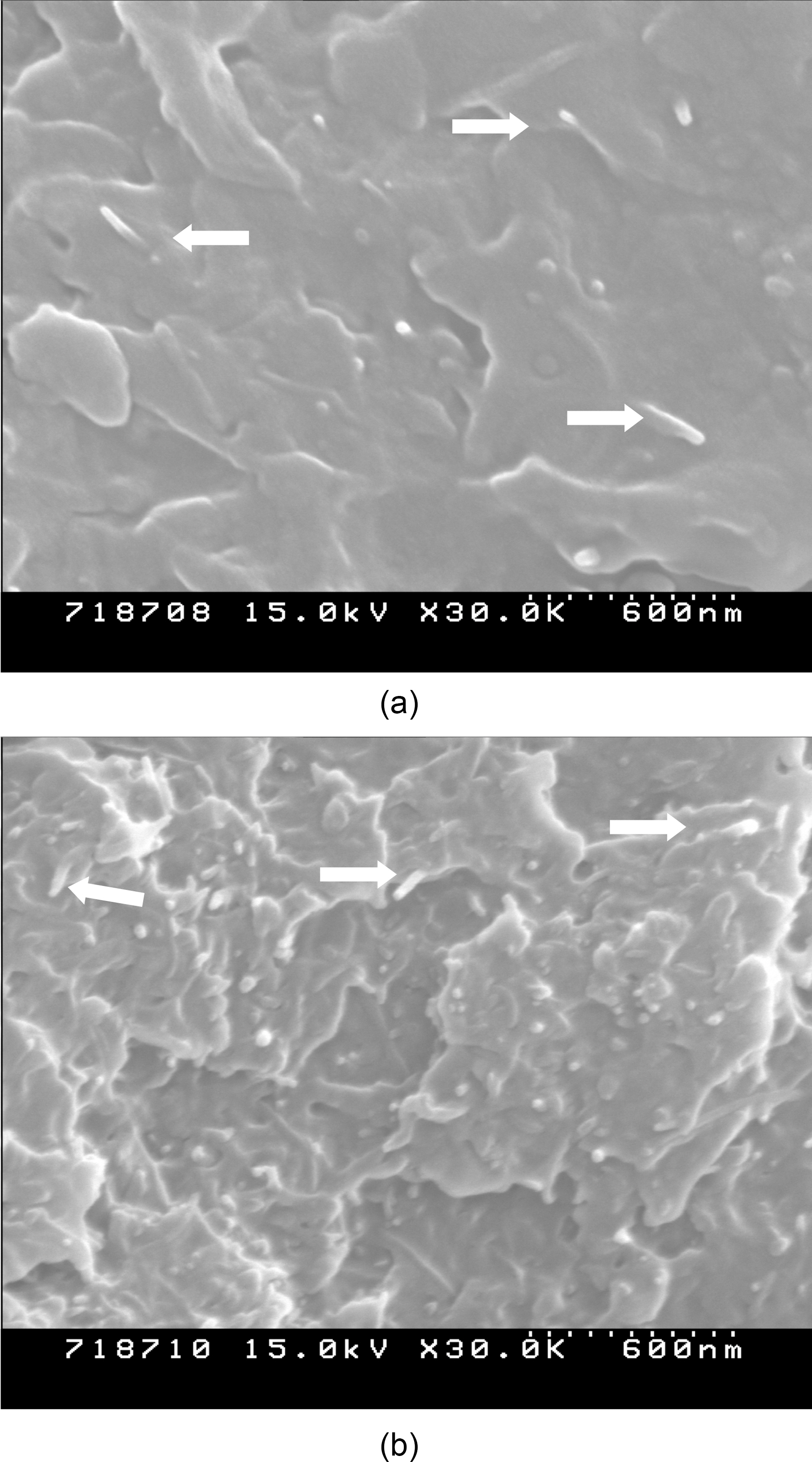

Fig. 5 shows the SEM images of GMA-MWCNTs/PP nanocomposites. From Fig. 5, white parts which are indicated by white arrows were GMA-MWCNTs embed in PP matrix. It can be seen that the GMA-MWCNTs were uniformly dispersed in the PP matrix without aggregation in the case of both low (0.5 wt%) and high (2.0 wt%) GMA-MWCNTs contents. This is due to the empowered compatibility between MWCNTs and PP matrix by GMAgrafting[20].

The viscoelastic behaviors of PP matrix are from intramolecular forces which were caused by polymer chain’s positioning in physicochemical bonding vectors and changes of strain from transformation of liquid state. In this study, the effect of GMA-MWCNTs on viscoelastic behaviors of PP matrix was investigated. It can be seen that the addition of GMA-MWCNTs caused viscoelastic changes of GMA-MWCNTs/PP nanocomposites. Additionally, the enhancement of interfacial interaction between GMA-MWCNTs and PP matrix could be affected to viscoelastic behaviors of GMA-MWCNTs/PP nanocomposites.

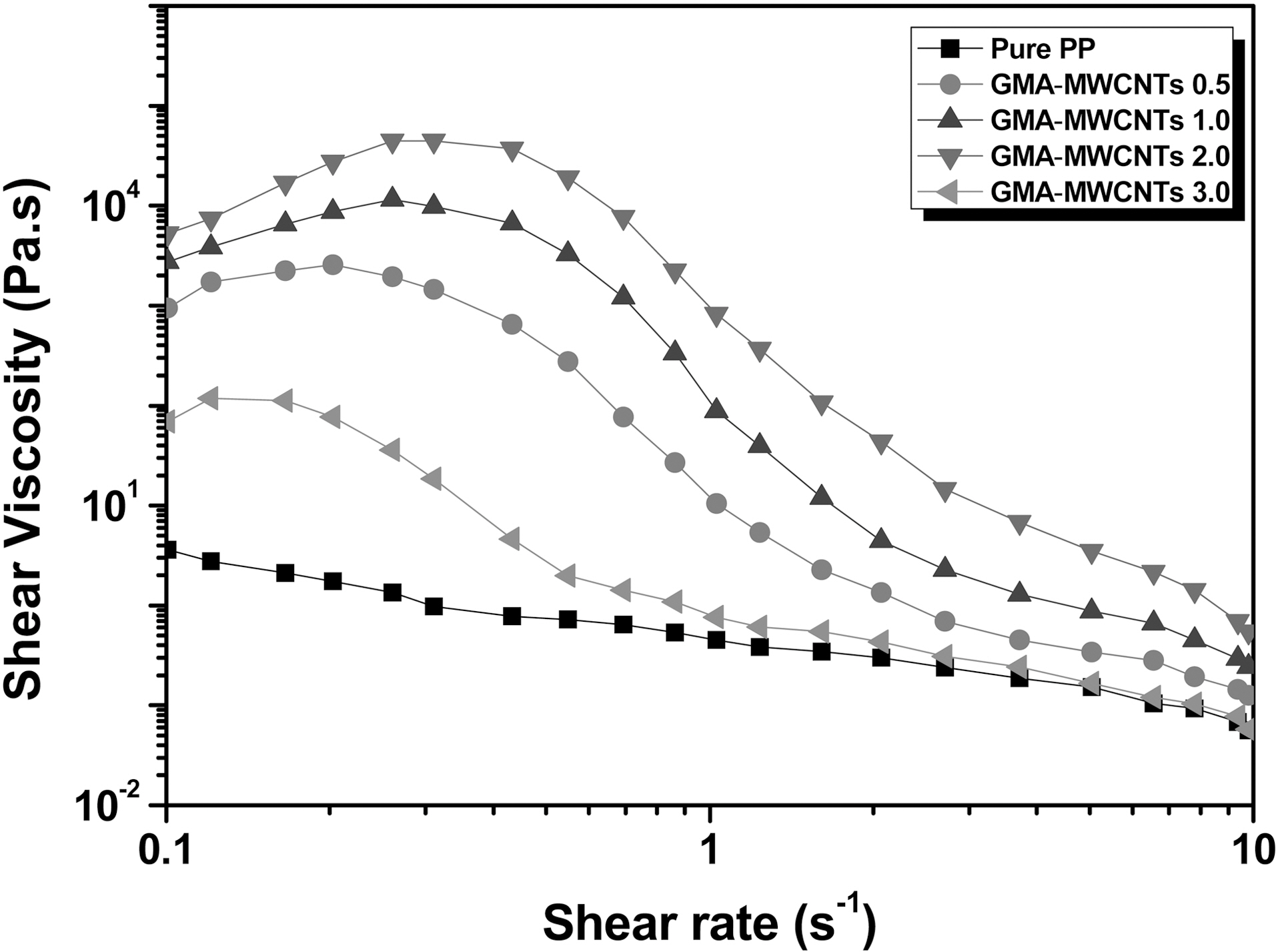

The results of the shear viscosity by measuring the steady share rate for the GMA-MWCNTs/PP nanocomposites are shown in Fig. 6. Because of intermolecular interaction between GMA-MWCNTs and PP matrix, it could be

predicted that the shear viscosity increased with increasing the GMA-MWCNTs content. As a result in Fig. 6, at the low frequencies, the shear viscosity of the GMA-MWCNTs/PP nanocomposites clearly deviated from the liquid-like behavior of the neat matrix with increasing the GMA-MWCNTs content. In other words, the pure PP exhibits the liquid-like behaviors at all frequency region and the viscosity of the PP increases as the GMA-MWCNTs increases. With addition of GMA-MWCNTs, the GMA-MWCNTs/PP nanocomposites show the non Newtonian behavior at low shear rate. It is attributed to the strong interaction between MWCNT-MWCNT, leading to non Newtonian behaviors of GMA-MWCNTs/PP nanocomposites at low shear rate [21]. With frequency rising, the shear viscosity of the GMA-MWCNTs/PP nanocomposites became Newtonian behavior. But in case of GMA-MWCNTs 3.0 sample, the shear viscosity had the lowest values in the GMA-MWCNTs/PP nanocomposites. It was seen that the excess addition of GMA-MWCNTs had influenced to decrease the shear viscosity, resulting from the aggregation of GMA-MWCNTs.

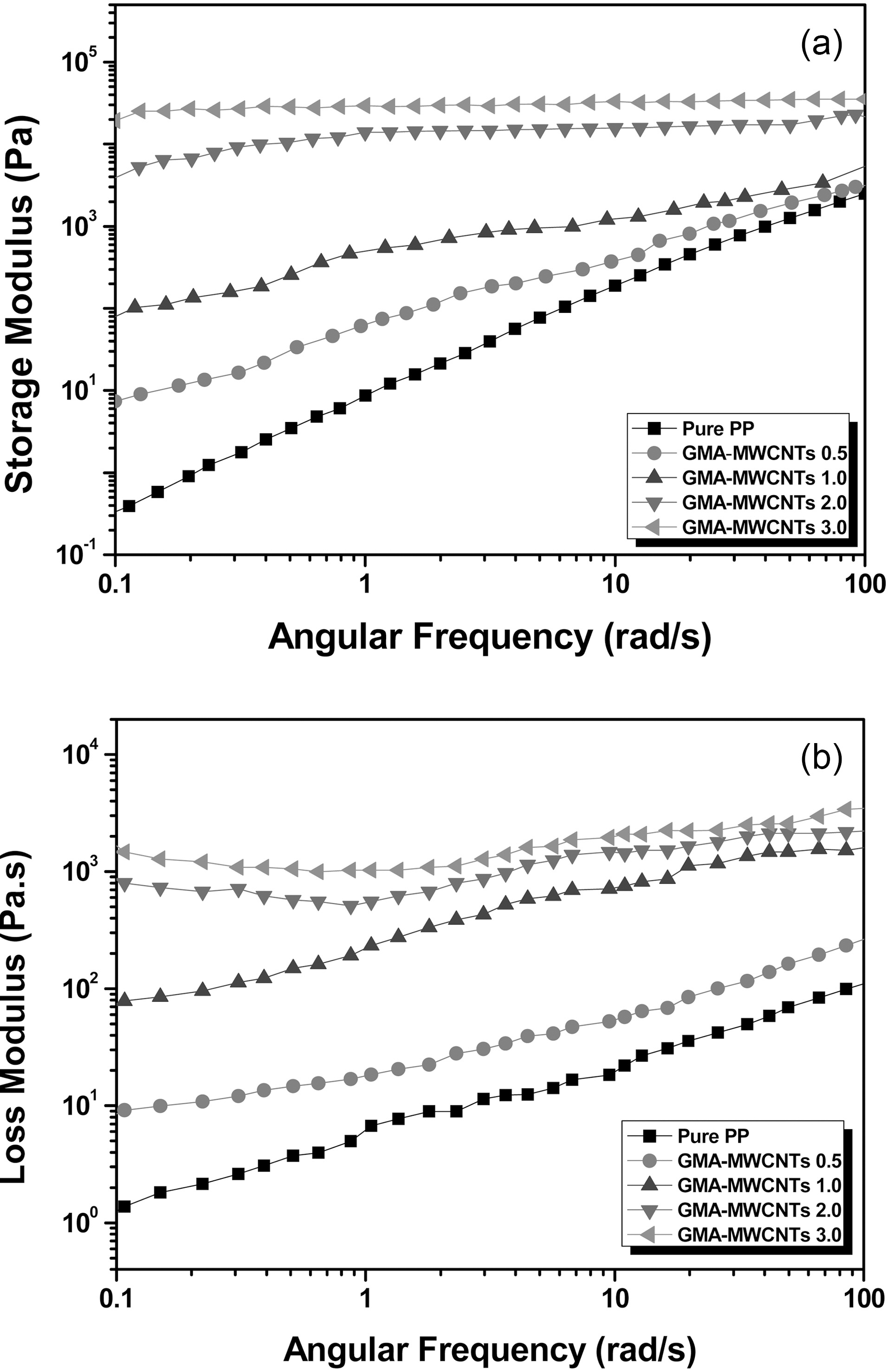

The changes of storage modulus (G') and loss modulus(G"), at different GMA-MWCNTs contents in PP matrix are shown in Fig. 7 (a) and (b). It could be found that G' and G" of PP matrix seem to reach the plateaus at low frequencies with relatively high GMA-MWCNTs content of 2.0 wt% and 3.0 wt%.

Fig. 7 (a) shows changes of the storage modulus. At low frequency, G' was increased with increasing GMA-MWCNTs content and frequency. In high frequency region,the increase of G' was reduced. Also, in Fig. 7 (b), loss modulus shows similar behaviors like storage modulus at all frequency region. It could be explained that the increase of GMA-MWCNTs content led to the formation of a CNT network and the transition from liquid-like to solid-like. These results provide the enhanced rheological properties by the improved interfacial interaction behavior between GMA-MWCNTs and PP matrix [22].

In this work, we investigated the viscoelastic behaviors of glycidyl methacrylate grafted multi-walled carbon nanotubes (GMA-MWCNTs)/polypropylene (PP) nanocomposites. The surface features of GMA-MWCNTs and the viscoelastic behaviors of GMA-MWCNTs/PP nanocomposites were investigated. As a result, rheological properties, such as storage modulus and loss modulus of neat PP were enhanced with increasing GMA-MWCNTs content. The shear viscosity was also increased with increasing GMA-MWCNTs content. Consequently, it was found that the chemical grafting of GMA on the MWCNT surfaces was affected to enhance the interfacial interaction between the MWCNTs and the PP matrix in this system.