It has been well established that polyacrylonitrile (PAN) fibers are one of the most suitable and widely used precursors for making high-performance carbon fiber, and PAN-based carbon fiber is stronger than other types precursor-based carbon fibers [1]. Developing carbon fiber from PAN based fiber generally involves three processes, namely stabilization, carbonization, and graphitization under controlled conditions. Among those processes, pre-oxidation is a very important step because it largely governs the final structure and mechanical properties of the carbon fiber. During this process in a temperature range of 180-280℃, PAN precursors are converted into infusible and nonflammable fibers with a ladder structure suitable for further carbonization [2]. Important factors such as temperature, time, and stretching have been studied previously [3-9]; however, systematic investigations of the effects of positive and negative stretching have never been reported relating to the structure and properties of PAN fibers in the pre-oxidation process.

In this work, the effects of positive and negative stretching on the structure and properties of PAN fibers in the pre-oxidation process were systematically investigated by using FTIR spectroscopy, XRD, and SEM observations.

The PAN fiber used in this experiment was supplied by Zhongfu Shenying Carbon Fiber Co., Ltd. (Lianyungang, People’s Republic of China) in tows of 1,000 fibers with an average density of 1.19 g/cm3 and a mean diameter of 12.4 ㎛.

2.2 Pre-oxidation of PAN fibers

Pre-oxidation was carried out in a furnace divided into nine temperature zones in a range of 180-300℃. Temperature gradually increased so as to control pre-oxidation temperature gradient. The stretching ratio was achieved by controlling the speed difference between the feed (v1) and take-up rollers (v2). The stretching ratio is determined by the follow equation: τ = [(v2-v1)/v1] × 100%, where if τ = 0, it means no stretching, if τ > 0, it means positive stretching,and if τ < 0, it means negative stretching.

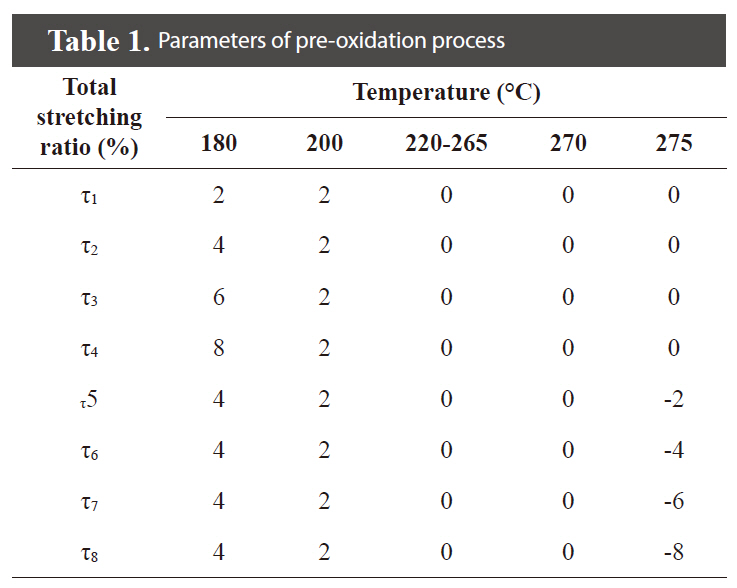

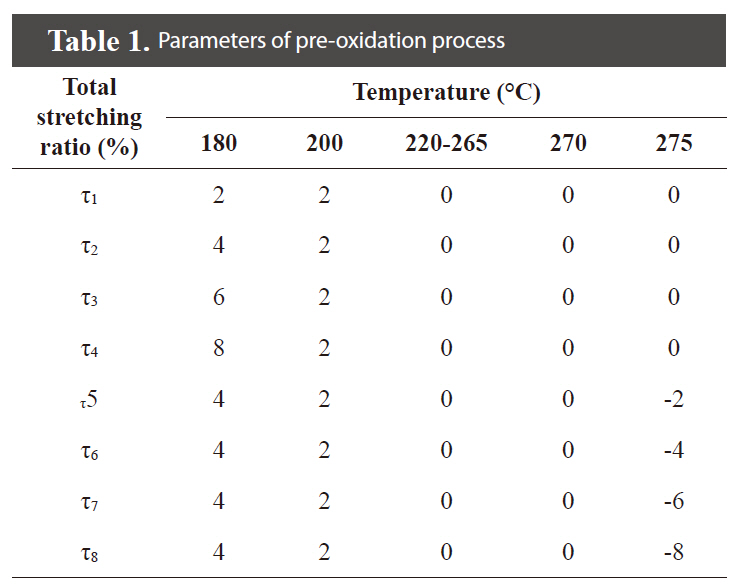

Table 1 shows various stretching ratios during the increase of the pre-oxidation temperature. τ1 means stretching ratio was 2% at 180℃, and it was increased 2% at 200℃ and then constantly sustained until 275℃. Therefore, the total positive stretching ratio was 4%. On the other hand, in the case of τ5, the fiber was relaxed 2% by supplying negative stretching at 270℃. Therefore, the total stretching ratio was also 4%; however, τ5 contained negative stretching.

[Table 1.] Parameters of pre-oxidation process

Parameters of pre-oxidation process

IR spectroscopy was performed to observe the effects of the pre-oxidation conditions. FTIR measurements were conducted through the loading of samples on KBr disks (0.5 mg sample mixed with 200 mg of KBr). The sample fibers were obtained from the production line after undergoing different treatments on a Nicolet-210 FTIR spectrometer with a resolution of 4 cm-1. The cyclization rate (we prefer the cyclization, not the relative cyclization rate) (η) is defined in terms of the intensities of the spectrocsopy peaks [10]:

where IC=N is the measured intensity of the conjugated band at 1630 cm-1 associated with the developing structure and IC≡N is the measured intensity of the nitrile band at 2240 cm-1 belonging to the unmodified PAN molecule.

A Rigaku X-ray powder diffractometer (Rigaku Co., Tokyo, Japan) was used to study the wide-angle XRD (WAXRD) pattern with CuKα radiation (wave length λ = 1.54 A) as a source. The step interval was 0.02°. The interplaner spacing (d-space) is determined by the Bragg equation:

where λ is the wavelength of the X-rays.

The aromatization index (AI) was determined by the following equation:

where Ia is the intensity of diffraction at 2θ = 25.5°, which is given by the ladder structure and Ip is the intensity of diffraction at 2θ = 17°.

The mechanical properties of the PAN pre-oxidized fibers were measured with a single fiber strength machine (YG004E, Ningbo Textile Machinery Co., China). In each case, at least 40 samples were tested. Discarding the top 5 and bottom 5, the average value of the remaining 30 can be automatically obtained. The diameter of each fiber was measured with a (Olympus) microscope before the tensile test.

2.6 Scanning electron microscope

The fractured surface of PAN pre-oxidized fibers were observed by using a field emission-SEM (Hitachi S-4700, Japan) with a revolution of 15 kV. Before observation, the samples were embedded in an epoxy resin and sputter-coated using Pt (JEOL JFC-1200, USA).

3.1 Positive stretching on the structure and properties

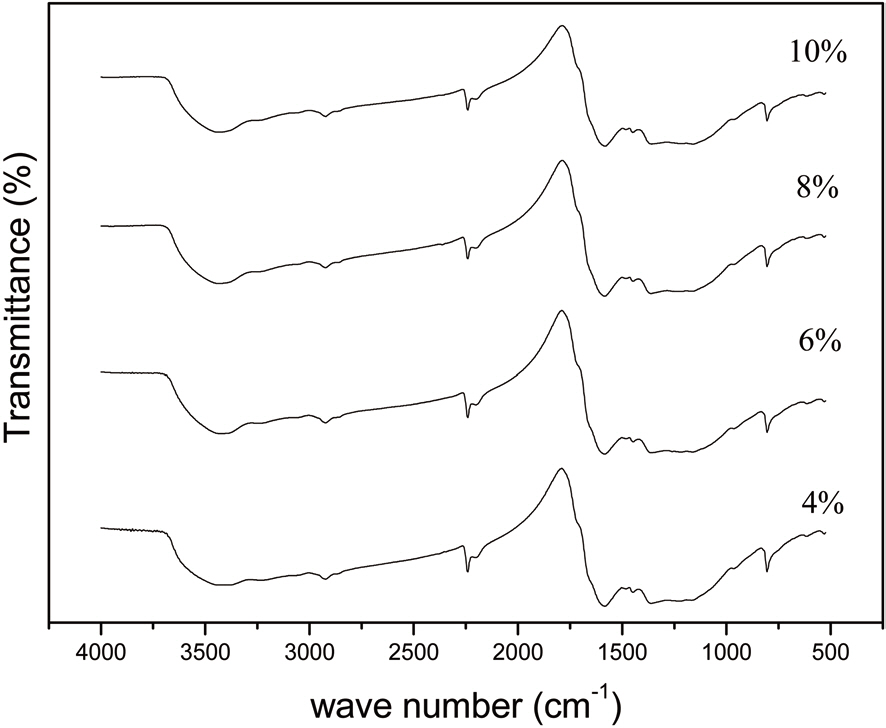

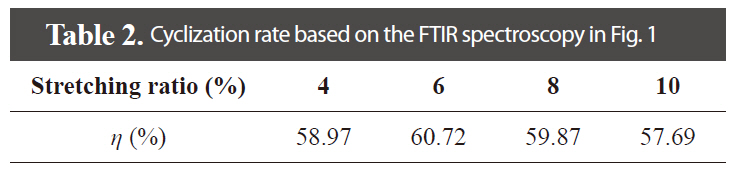

Fig. 1 shows the FTIR spectroscopy of the pre-oxidized PAN fibers at different positive stretching ratios. The positive stretching ratio did not show any influence on the movement and intensity of the functional groups until 10%. There were weak absorption bands at 2243 cm-1 assigned to the nitrile group and, at 1581 cm-1, were assigned to the vibration of carboxyl groups, which indicated that oxidation has occurred. The cyclization rate was calculated according to Eq. (1) based on Fig. 1 and is listed in Table 2.

Fig. 1 shows there is no obvious influence on the movement and intensity of functional groups of FTIR, and the cyclization rate is also affected less, which indicates that positive stretching cannot affect the chemical structure.

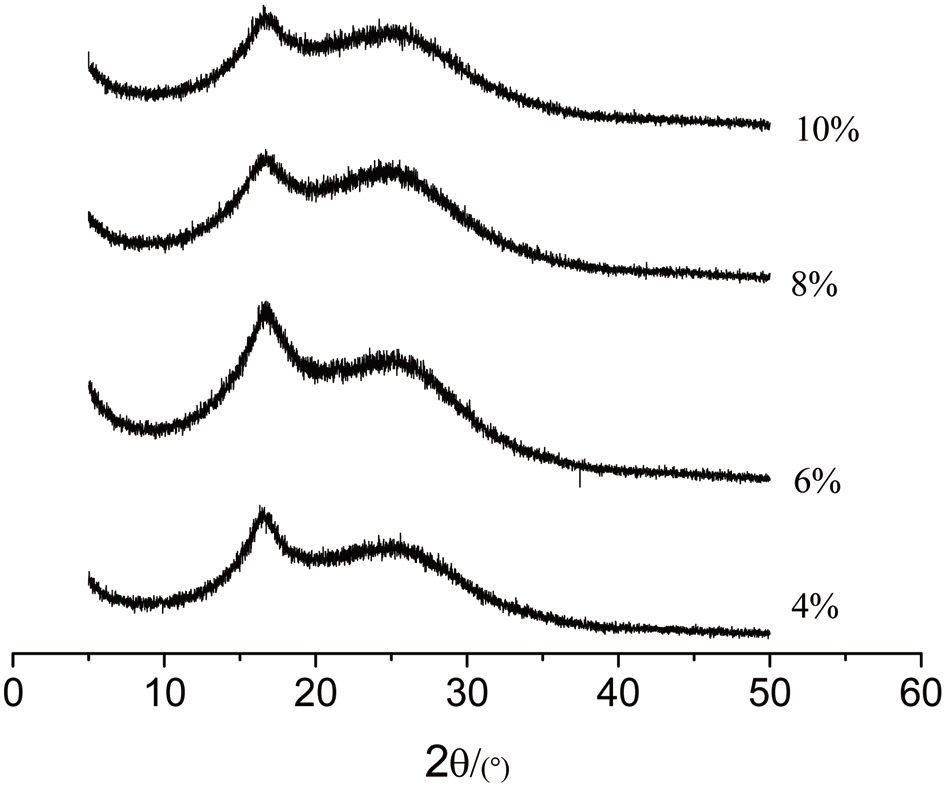

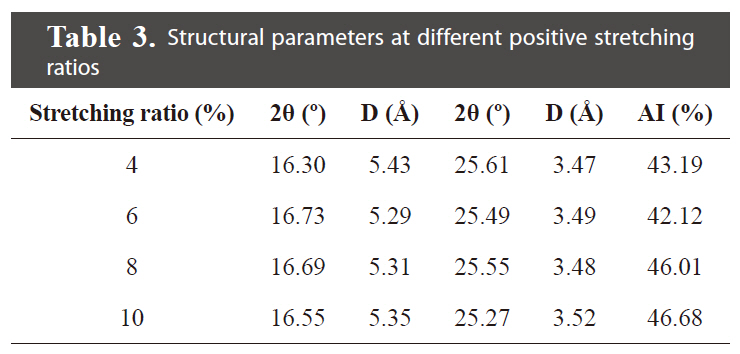

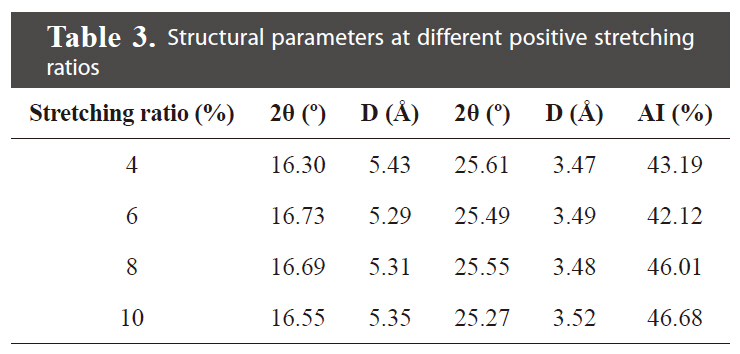

Fig. 2 shows the WAXRD patterns of pre-oxidized PAN fibers at different positive stretching ratios. The spectra of pre-oxidized PAN fibers shows a weak diffraction at 2θ = 17° and a broad diffraction at 2θ = 25.5°. According to Eqs. (2) and (3), structural parameters were calculated and listed in Table 3. The d-spacing of diffraction at 17° was 5.29 A, obtained from a stretching ratio of 6%. However, the d-space diffraction around 25.5° shows an increased trend. The AI

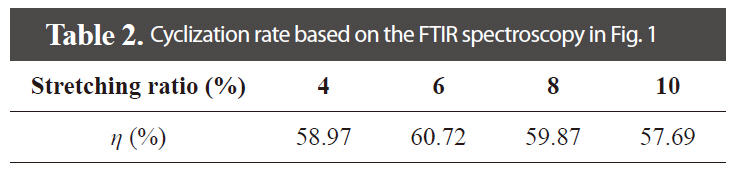

[Table 2.] Cyclization rate based on the FTIR spectroscopy in Fig. 1

Cyclization rate based on the FTIR spectroscopy in Fig. 1

values increased with an increase in the stretching ratio, indicating that stretching promoted the reactions. In fact, stretching affected the readjustment of the molecular chains (involving the rotation of nitrile groups around the C-C single bond) not only in the ordered domains but also and especially in the disordered domains. This might have brought more nitrile groups into a suitable position for cyclization. So, one can conclude that stretching offers molecular chains additional energy to readjust and pack into an ordered phase, which is accordant to the results of Wu

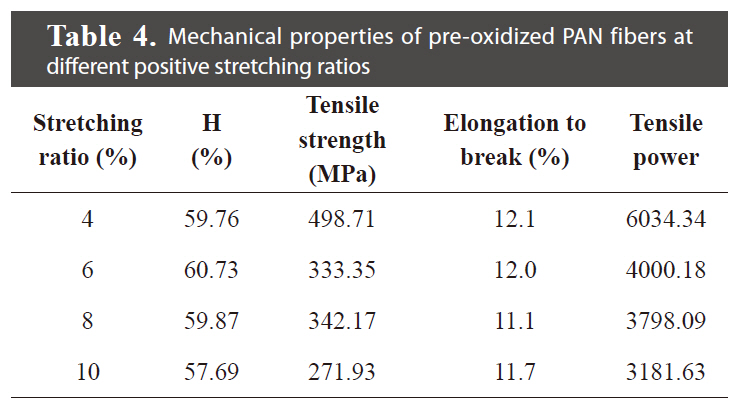

Although the tension evolution during the pre-oxidation of PAN fibers has been investigated [4], the mechanical properties of pre-oxidized PAN fibers should also be tested, and they were

[Table 3.] Structural parameters at different positive stretching ratios

Structural parameters at different positive stretching ratios

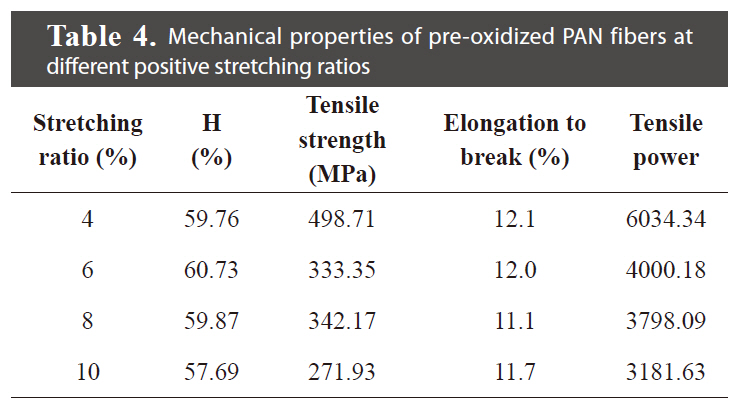

[Table 4.] Mechanical properties of pre-oxidized PAN fibers at different positive stretching ratios

Mechanical properties of pre-oxidized PAN fibers at different positive stretching ratios

listed in Table 4 in increasing order of the positive stretching ratio. The tensile strength and tensile power of the

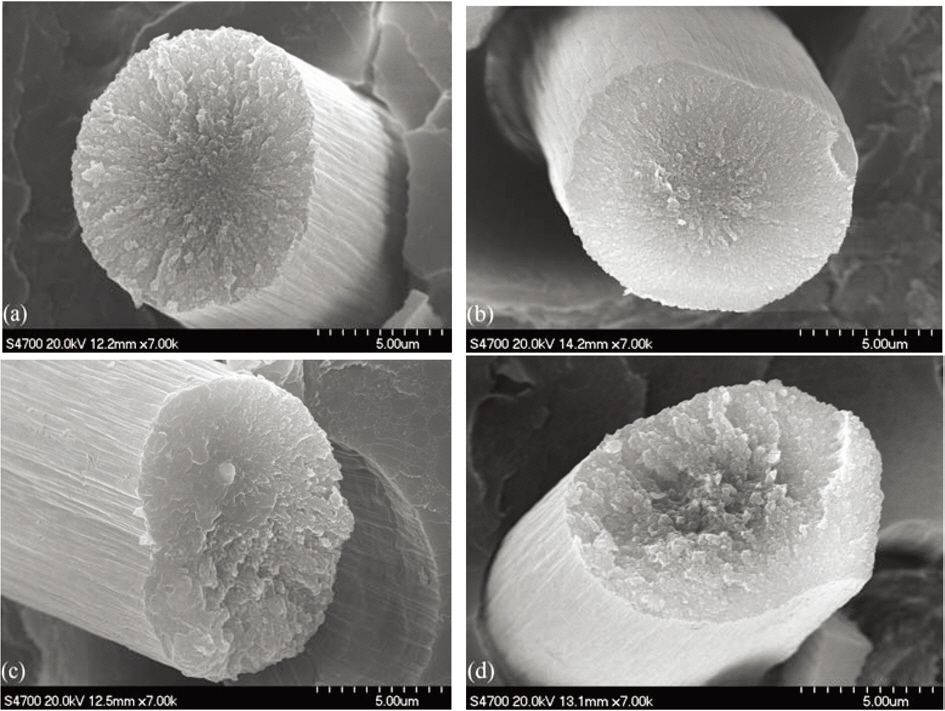

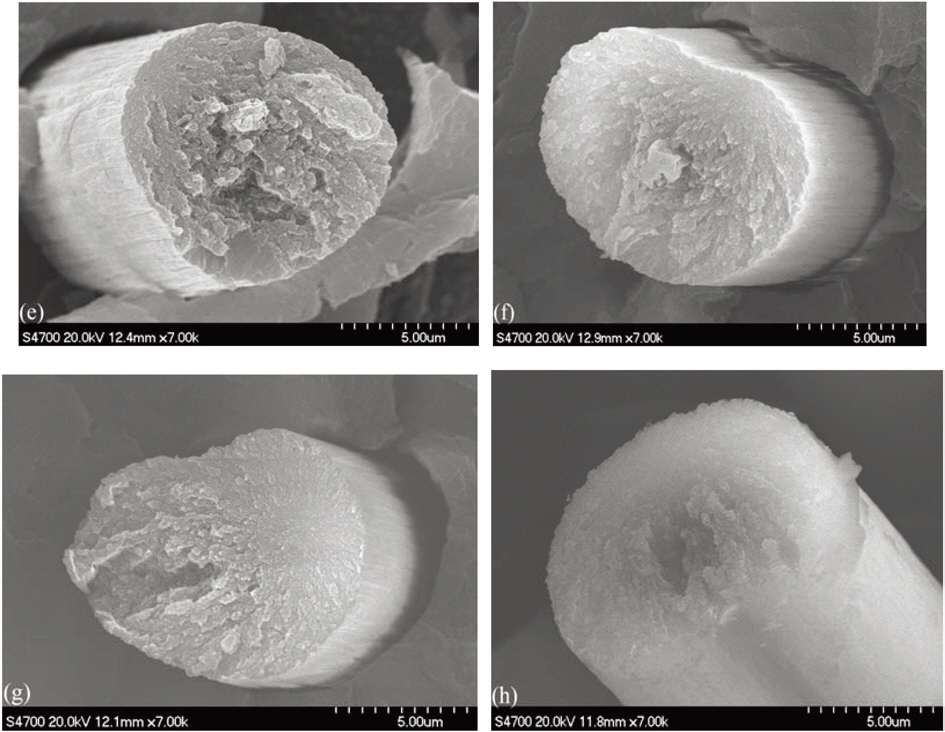

PAN fibers for the 4% stretching ratio were higher than those of the other three samples and had a decreasing trend. However, there was no obvious difference among the elongation to break. Tensile power stands for the work involved in breaking the fibers and could be defined in terms of the product of strength and tensile power. Fig. 3 shows the SEM images of pre-oxidized PAN fibers at different positive stretching ratios. When the stretching ratio is at 4% (Fig. 3a), the fractured surface radiates from the center to the surrounding is and distributes equally, indicating that the internal binding force of fibers are large and the tensile strength and tensile power are larger. When the stretching ratio was at 6% (Fig. 3b), the toughness decreased and the fractured surface became smooth, resulting in a dramatically drop in tensile strength and tensile power. When the stretching ratio was at 8% (Fig. 3c), the fractured surface of pre-oxidized PAN fibers became rough, and the tensile strength increased a little. When the stretching ratio was at 10%, it prevented penetration into the PAN molecule and broke the molecular order and orientation so that the pre-oxidation was insufficient with large radial differences, resulting in uneven molecular structure and decreased tensile strength. As shown in Fig. 3d, the fractured surface is quite rough, implying that the internal stress was not equal and bonding force decreased, and then the tensile strength and tensile power decreased. In a word, the tensile strength and tensile power have the same performance. It is necessary to consider the tensile strength and tensile power to obtain both the elongation and strength so that it performs well when it is used; meanwhile, the stretching ratio should not be too large so as to avoid performance degradation [11]. Except for the results above, the evolution of structure and the changes of properties during the pre-oxidation on other important aspects have been studied by Zhang

3.2 Negative stretching on the structure and properties

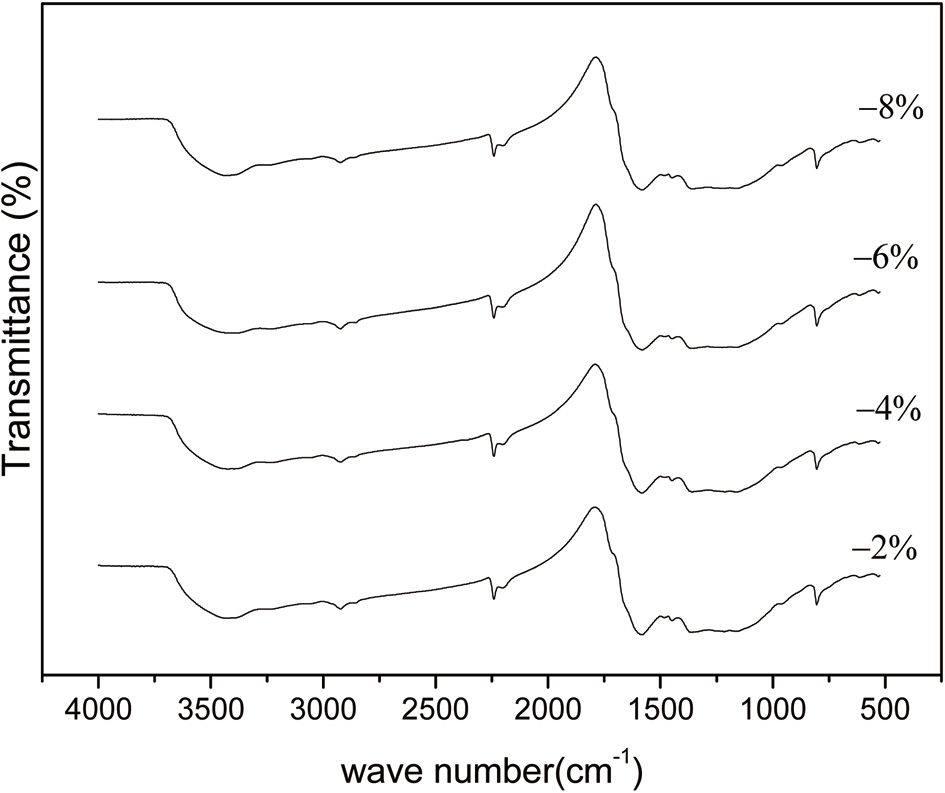

Wang

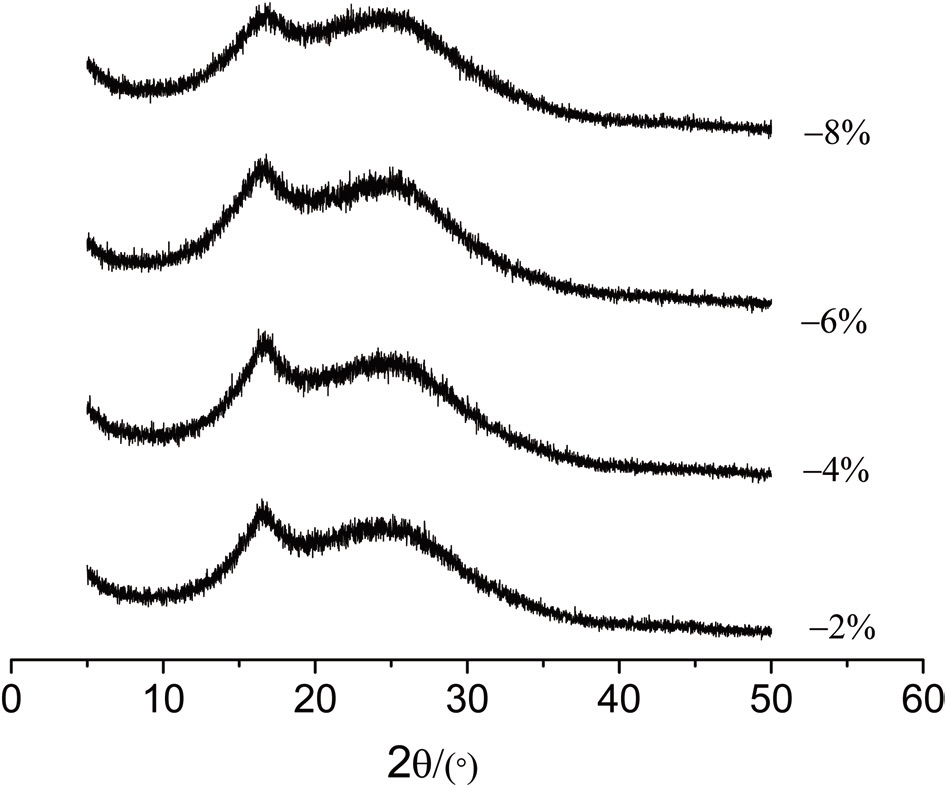

Fig. 5 shows WAXRD patterns of pre-oxidized PAN fibers at different negative stretching ratios. In general, the spectra of pre-oxidized PAN fibers showed weak diffraction at 2θ = 17° and a broad diffraction around 2θ = 25.5°. There are no obvious differences the ratios decrease.

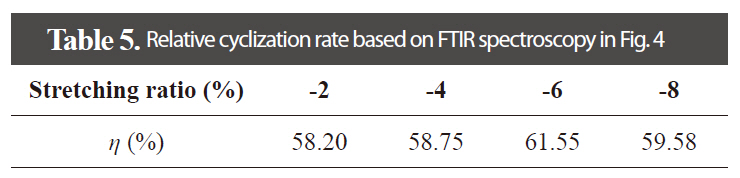

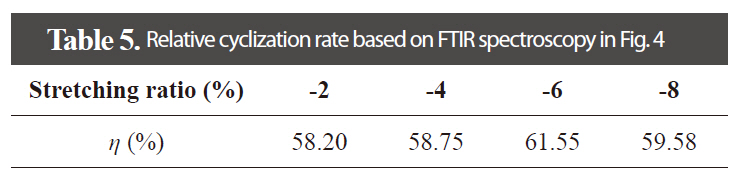

[Table 5] Relative cyclization rate based on FTIR spectroscopy in Fig. 4

Relative cyclization rate based on FTIR spectroscopy in Fig. 4

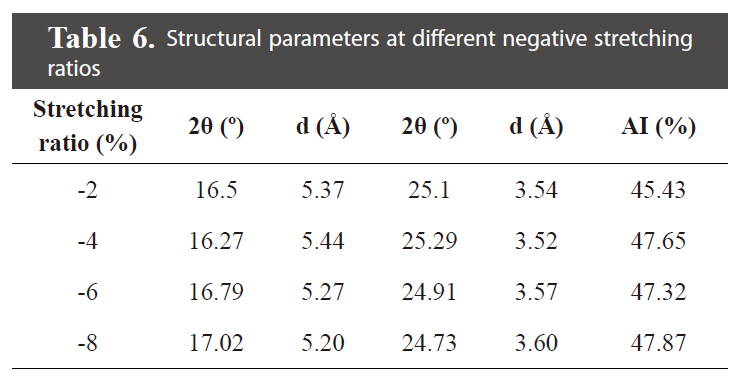

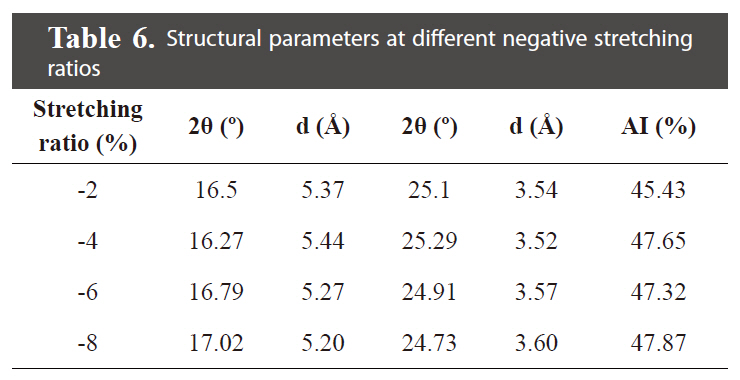

[Table 6.] Structural parameters at different negative stretching ratios

Structural parameters at different negative stretching ratios

Structural parameters were calculated according to Eqs. (2) and (3) and were listed in Table 6. When the stretching ratio was -4%, the d-spacing diffraction at 17° and around 25.5° were the higher and lower than the other three samples, respectively; however, the AI values increased with an increase in the negative stretching ratio.

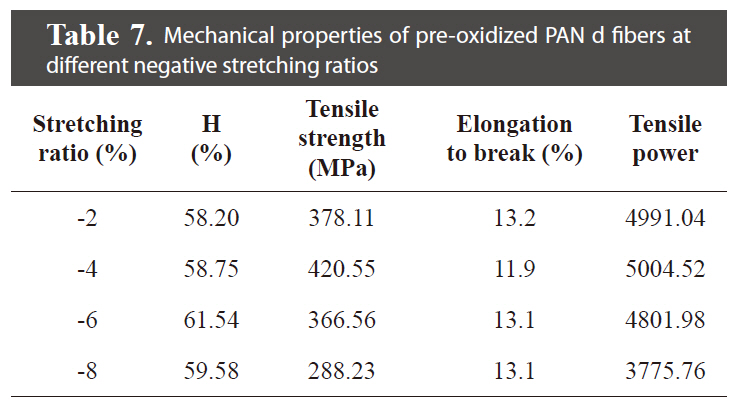

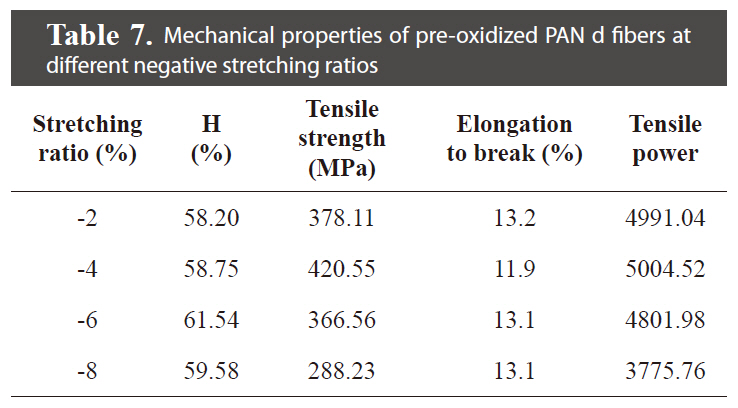

Table 7 shows that relative cyclization rate was the highest but not the tensile strength, indicating that the oxygen entered the PAN molecule chain easily but may have caused an overreaction, resulting in the decreased tensile strength. When the stretching ratio was -4%, the tensile strength of the pre-oxidized PAN fibers was higher than the other three groups, but the elongation at break was lower than the other three groups, of which the elongations to break of the three groups were nearly the same; nevertheless, the tensile power of the former three groups was nearly the same but higher than that of the stretching ratio -8%. Meanwhile, as shown in Table. 4 and Table 7, the elongation to break the pre-oxidized PAN fibers after the negative stretching was higher than that of the positive stretching. When the stretching was -2%, because of the drastic

Mechanical properties of pre-oxidized PAN d fibers at different negative stretching ratios

oxidation, it was difficult for oxygen to enter the PAN molecule, and this resistance caused the oxidation to not occur easily, resulting in the uneven structure of the pre-oxidized PAN fibers. Fig. 6 shows SEM images of pre-oxidized PAN fibers at different negative stretching ratios. When the stretching ratio was -2% (Fig. 6e), the fractured surface showed an uneven stress of internal molecules and could not spread after the tensile force; therefore, the tensile strength was not very high. When the stretching ratio was -4%, this was helpful for oxygen to penetrate into PAN molecular chains to oxidize and form an equal structure of pre-oxidized PAN fibers. The SEM image (Fig. 6f) also showed a better fractured surface than the other three groups of samples. As the stretching ratio was increased to -6%, oxygen molecules could penetrate into PAN molecular chains to peroxide and result in a decrease in tensile strength, but the elongation to break increased. When the stretching ratio was -6% (Fig. 6g), the fractured surface was rougher than that of pre-oxidized PAN fibers at a stretching ratio of -4%, and some obvious crack can be also seen clearly. When the stretching ratio increased to -8%, excessive oxygen molecule penetrated into the internal PAN molecular chains, but it was too late to deoxygenate and dehydrogenate before the oxidation was completed. As shown in Fig. 6h, it is hard to see the obvious fractured surface, indicating that the oxidation was rather excessive. Meanwhile, excessive negative stretching made the fibers too relaxed, resulting in irregular internal distribution of the PAN molecular chain, leading to low tensile strength and tensile power. Consequently, when the negative stretching ratio was in the range between -2 and -4%, the properties of PAN fibers performed well.

PAN fibers were pre-oxidized at different stretching ratios in the range of 180-275℃. The tensile strength of pre-oxidized PAN fibers decreased gradually with an increase in the positive stretching ratio. There is no obvious influence on the chemical structure, whether the stretching is positive and negative; however, the crystal structure was affected by them, and the positive stretching affected the readjustment of the molecular chains and might have brought more nitrile groups into a suitable position for cyclization. The maximum strength is 479.81 MPa when the stretching is positive and the maximum strength is 420.55 MPa when the stretching is negative.