Currently thin film gas sensors for toxic gases have attracted much attention due to the growing concern for environmental safety. A number of semi-conductive oxides such as ZnO, SnO2 and In2O3 have been used for different gas sensors [1-3]. Most of these gas sensors are based on a variation in resistance when the film sensors are exposed to target gases. Recent research has shown that the transparent and conducting Sn doped In2O3 (ITO) offers new advantages in the design of metal oxide-based gas sensors. ITO has high gas sensitivity, because its conductivity increases remarkably when exposed to reducing gases. Since most oxide semiconductor gas sensors operate at relatively high temperatures, a heater is required. The integration of a heater not only increases the power consumption but also the complexity of the device. Moreover, reactive gases having low boiling points require care in design to prevent reactions due to the high temperatures generated by the sensor heater. Thus, it is highly desirable to decrease the required operating temperature for viable gas sensors in industrial applications [4,5].

In this study, a sandwich structure of ITO 50 nm/Au 5 nm/ITO 45 nm (IAI) multilayer films and ITO single-layer film sensors were prepared on glass substrates without intentional substrate heating, and then the effects of the Au interlayer on the sensitivity for detecting methanol vapor were investigated at room temperature. The specific goal of this study is to improve the sensitivity of ITO film sensors with regard to methanol vapor detection at low operating temperatures.

2.1 The film sensor deposition

The deposition of the ITO and Au thin films was performed in a magnetron sputtering system that was equipped with two cathodes. RF (13.56 MHz) and DC power were applied to the ITO (In2O3 90% - SnO2 10%, purity; 99.99%) and the Au (purity; 99%) targets, respectively. ITO and IAI films were deposited onto glass substrates (Corning 1747) at 70℃ without intentional substrate heating. The substrate temperature was detected by a K-type thermocouple directly in contact with the substrate surface.

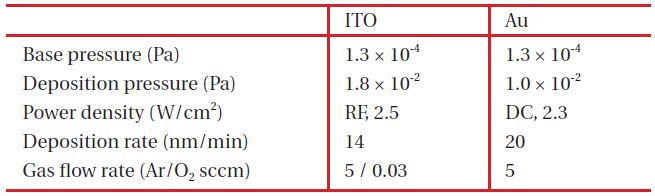

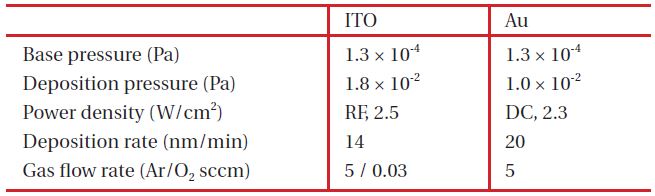

[Table 1.] The deposition conditions of the ITO and Au thin films.

The deposition conditions of the ITO and Au thin films.

The deposition distance between the target and rotation substrate holder was held constant at 10 cm. The substrate rotation speed was set to 10 rpm for all the depositions. By controlling the deposition time, the thickness of the ITO and IAI films were kept constant at 100 nm and 50/5/45 nm, respectively. Table 1 summarizes the process conditions used in this study. A Cu-Ka X-ray diffraction (XRD) was used to observe the thin film crystalline structure. The average surface roughness (Ra) was measured on 2 × 2 μm2 areas with a tapping mode atomic force microscopy (AFM) under ambient conditions. The Ra of the bare glass substrates was 1.5 nm. The electrical conductivity was evaluated with Hall Effect measurements [6].

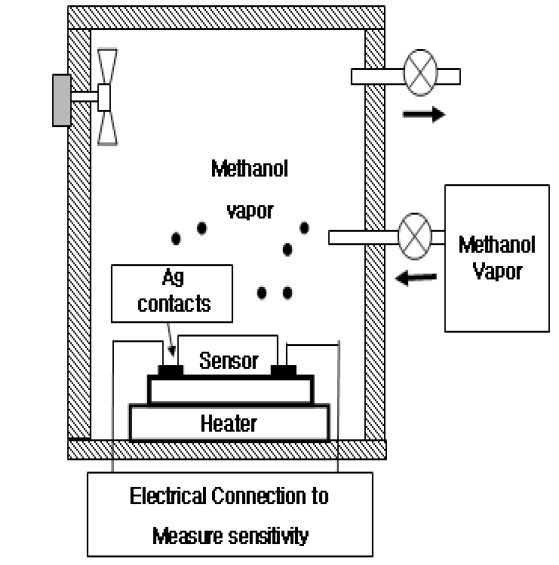

All of the gas sensing measurements was carried out at room temperature. Ag electrodes (0.5 cm2) for measuring the sensitivity to methanol vapor were deposited onto the prepared sensors by thermal evaporation. Figure 1 shows the schematic diagram of the static measurement set-up used to measure the sensitivity to methanol vapor. A detailed description of these devices can be found in [5]. In this study, the methanol vapors were injected into the test chamber using a calibrated syringe. The gas concentration was varied from 100 to 1,000 ppm. The measurement of the sensor resistance was carried out using a high impedance electrometer. The sensitivity (S) of the ITO film sensor was determined using the following equation [5]:

S = (Rvap - Rair) / Rvap

where Rvap is the resistance of the film sensor in the presence of methanol vapors and Rair is the resistance in air, which should be a constant for a given test temperature. After the gas sensing, the film sensors were heated to 80℃ for 10 minutes. This enabled the methanol to vaporize and did not allow surface condensation to occur on the film sensor.

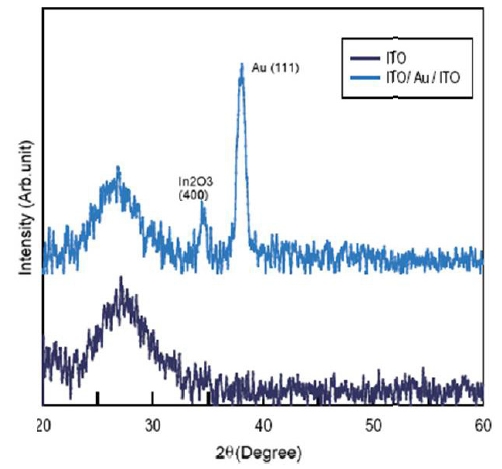

It is well known that ITO films deposited by magnetron sputtering at low temperatures are usually amorphous [7]. Figure 2 shows the XRD pattern of the ITO and IAI films. The as-deposited ITO films did not exhibit any diffraction peaks, whereas the IAI films showed diffraction peaks corresponding to the Au (222) and In2O3 (100) planes. This means that the Au intermediate layer is very effective in crystallizing the ITO films.

Similarly, Y. Kim et al. reported that the ITO films deposited on the Au coated polymer substrates crystallized without intentional substrate heating [8].

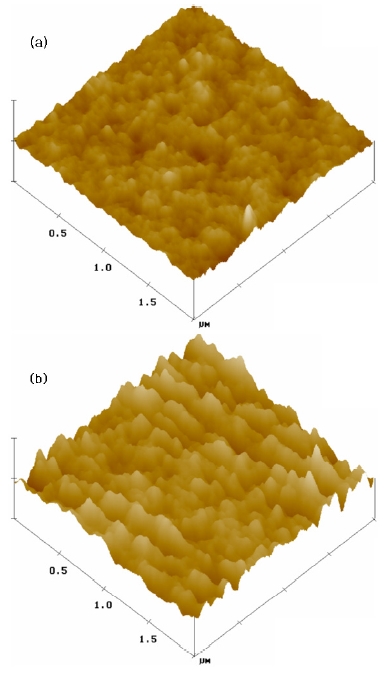

Figure 3 shows the three-dimensional AFM images of the ITO and IAI films. The ITO single layer film in Fig. 3(a) had a Ra of 1.9 nm, while the Ra of the IAI film in Fig. 3(b) was 2.4 nm. The rougher surface morphology of the IAI films is attributed to the grain growth of the ITO films, which is corroborated by the XRD peaks of Au (222) and In2O3 (100).

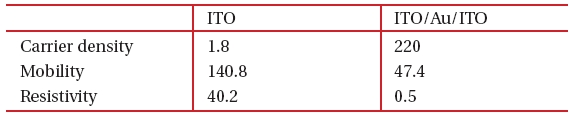

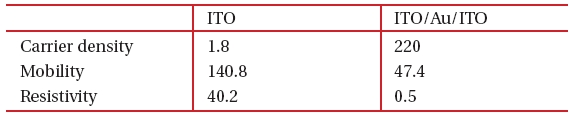

The comparison of the carrier density (× 1019/cm3), mobility (cm2/Vs) and resistivity (× 10-4 &Ω.cm) of the ITO and ITO/Au/ITO films.

Table 2 shows the electrical properties of the IAI and ITO films evaluated with Hall Effect measurements. In general, the resistivity of the ITO films depends on the carrier mobility and the carrier density. The ITO films have a higher mobility than the IAI films, suggesting that the two interfaces between the ITO and Au film may act as a barrier to carrier movement. Although ITO/Au/ ITO films have a lower mobility than ITO single-layer films, they have a lower resistivity. The decrease in the resistivity of the IAI films may be caused by the increase in the carrier density of the IAI films, which results from the presence of the Au interlayer.

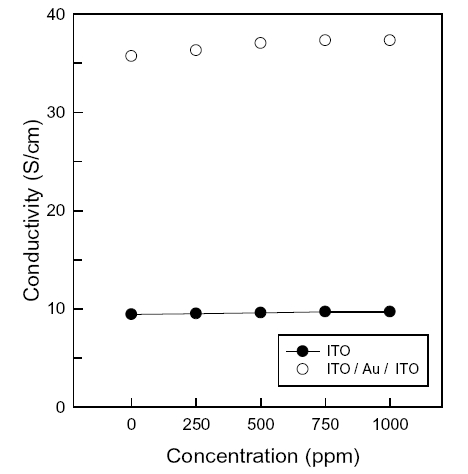

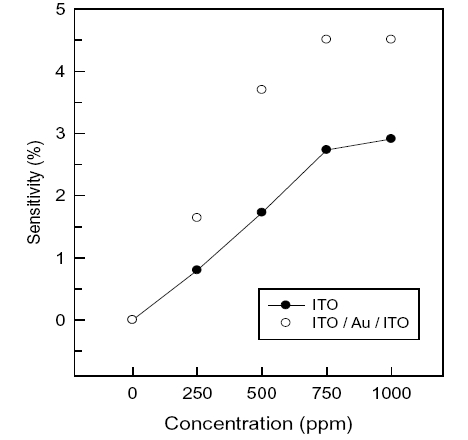

Figure 4 shows the variation in the electrical conductivity of an ITO and IAI film sensor with different concentrations of methanol vapors. The conductivity increases upon exposure to the methanol vapor. Figure 5 shows the variations in the sensitivity due to the methanol vapor concentration. The sensitivity increases with the gas concentration and the IAI sensors show a higher sensitivity by a factor of about 1.6.

From Figs. 2 and 5, it can be concluded that the conductivity increases due to the ITO crystallization by the Au interlayer, resulting in an improved sensitivity towards the methanol vapors. It is observed from Fig. 3 that the Au interlayer increases the surface roughness of the ITO film and crystallizes the films. The improvement in the crystallite growth may provide more surface area, thereby increasing the opportunities for interaction with the gaseous species.

Moreover, the improvement in crystallization increases the mean free path of the carrier in the lattice of the film. Because of this, the carriers generated have a lesser chance of scattering within the lattice. This may contribute significantly to the improvement in the response of the film sensor. The sensitivity of the ITO film sensors decayed about 15% from 2.9% measured at 1,000 ppm over a time period of 600 hours, while the sensitivity of the IAI film sensors decayed only 3% from 4.5% measured at same methanol vapor concentration of 1,000 ppm. Therefore, the IAI films showed an improved gas sensing stability.

ITO/Au/ITO (IAI) multilayer film sensors show a higher conductivity than that of ITO film sensors, due to the higher carrier density found in the IAI films. The conductivity of both types of film sensors increases upon exposure to methanol vapor, and the sensitivity of both types of film sensors towards methanol increases with the gas concentration. IAI film sensors, which have a crystallized structure and a higher carrier density show a higher sensitivity than that of the ITO film sensor.

In this study, a significant improvement in the sensitivity for the detection of methanol vapors is observed by applying an Au intermediate film between the ITO films. This approach is promising for gaining improvement in the performance of gas sensors at room temperature.