Hydrocarbon oils have been put to numerous commercial and industrial uses for decades. However, in recent times, researchers have attempted to discover a novel substitute of renewable origin in place of mineral oils. This is because the application of mineral oils creates environmental pollution that is noxious to all plants, animals and humans. It has been documented that a significant number of all job-related diseases of machinery users are as a result of skin contact with fluids utilized in operations [1]. For instance, in the United States, record showed that around 700,000 out of a million workmen are vulnerable to these fluids during metalworking operations. The special chemical formulation of these fluids as well as the quantity of bacterial toxicants contained in them damages the human skin, resulting allergies or irritation [1]. Moreover, mineral oils have detrimental consequences since atmospheric pollution contributes to production of greenhouse gases and global warming[2].

In addition, the reserve of mineral oil is limited and will likely deplete in the near future. The accessibility of mineral oil is also extremely subject to political review. Due to these challenges, scientists have done a lot of research so as to discover a substitute for mineral oils. Vegetable oils are good substitutes because they possess numerous benefits including being renewable, environmentally friendly, cost effective, as well as being effortlessly controllable. They also have straightforward manufacturing procedures where there is a serious demand for contemporary kinds of energy. Consequently, in current times, many researchers have explored ways to utilize oil from vegetable to produce different types of oils such as biofuel oils, diesel, etc.[3].

Research done has brought about new approaches on how to produce oil from biomass such as quick pyrolysis, thermochemical operation, and vacuum pyrolysis along with flash pyrolysis[4]. For instance, a study was performed on hydrocarbon-established industrial lube and palm oil for engine utilization. Parameters such as viscosity, wear, friction, lube degradation along with discharge were compared in a similar test environment[5]. The impact of viscosity, friction and wear on tribological characteristics of blended palm oil were examined. They demonstrated that, at reduced load along with temperature, wear amounts observed when applying palm oil methyl ester lubricant were low (below 5%) while at increased load, higher wear amounts were observed [5]. Viscosity value was also found to diminish with a rise in temperature and rise with elevated load[6].

Various biodegradable oils, specifically vegetable-based oils, have satisfactory lubricating capacity which is generally more effective than hydrocarbon or standard artificial oils[7]. Use of vegetable-based oil products provides an avenue for invigorating rural economic development for the sole reason that agriculturist will profit from the rising demand for oils obtained from vegetable. Numerous vegetable oils including soybean, palm, canola, rapeseed and sunflower have been employed to develop lubes[8]. Environmental pollution created by hydrocarbon oil is a primary challenge which cannot be overlooked. Oil discharge into water bodies and land may occur because of human negligence which could result in leakage of petroleum crude oil or used engine fuel. Within the sea, lube leak could occur from the offshore petroleum platforms or petroleum tankers. Records show that the entire amount of petroleum wasted into the atmosphere from 2010 to 2015 was about 33,000 tonnes. Out of this, 11 cases involved discharges involving over 700 tonnes of oil each[9].

Oil leak can generate problems for humans and other forms of life. Oil floating on the water hinders the passage of sunlight through it, making it impossible for aquatic life to survive. In light of this, the study of bio-lubricants as a replacement lube to hydrocarbon oil has gained growing awareness. Bio-lubricants are produced from recoverable base supplies like vegetable oil. Unlike mineral oil, biolubricants are less poisonous and completely biodegradable which implies that they are more environmentally friendly [10]. The chemical structure of vegetable oil comprises of fatty acids and glycerol called triglycerides. This triglyceride is an ester obtained from individual molecules of glycerol connected chemically to three fatty acids. Fatty acids are biological polar atoms made up of a carboxyl set within its series. Metal surfaces are attracted to one end of its atom due to the polarity of the fatty acid, while at the other end, the surfaces are repulsed. This phenomenon is called physical uptake which comprises of intermolecular forces such as Van der Waals. It is also capable of giving a single atomic film that reduces friction over the metal surfaces. In addition, chemical adsorption, also known as chemisorption, is an alternative uptake system demonstrated by fatty acids over surface of metals. It entails diverse levels of chemical bonding between the metal surfaces and carboxyl sets by means of electrons shared with the under layer atoms[11].

Canola oil is obtained from a type of rapeseed that has low erucic acid. Canola was discovered in Canada in 1979 as a comestible oil crop made at that time using breeding methods, and distinguished by low erucic acid rapeseed, as well as small amounts of glucosinolates. In several nations such as Canada, the phrase ‘rapeseed oil’ refers to the oil for industrial application, while ‘Canola’ applies to the edible cooking oil. However, in the United Kingdom, ‘rapeseed oil’ refers to both the industrial and cooking forms of the oil and the term ‘Canola oil’ is seldom used[12]. The canola oil contains a high concentration of oleic acid, low levels of stearic acid and little or no palmitic acid. It is, therefore, relatively low in saturated fatty acids, thereby permitting its most optimal use in applications where low-temperature characteristics and pour point are crucial. Owing to the fact that canola oil is among the global main edible oils, it is accessible in huge amounts and at quite affordable cost both of which are essential considerations for its universal lubricant utilization. The main industrial applications of canola-based oil are in automobiles, lifts, bridges, dams and waterways. Other lubricant applications of canola oil incorporate metal-working fluids, chain-saw lubricants as well as concrete and tile mold release tools[13].

Despite their usefulness, there are certain drawbacks of oils obtained from vegetable including their lower viscosity which influences their effectiveness during friction and wear operation. As such, an examination is required to assess the lubrication system of oil from vegetable so as to evaluate its potential application as a bio-lubricant in industrial operations. In this study, the investigators estimated the level of friction employing the American Society for Testing and Materials (ASTM) standards among canola and paraffin oils. Investigators utilized pin on disc tribotester, Brookfield viscometer and scanning electron microscope (SEM) in the course of this research.

2. Research Methods and Contents

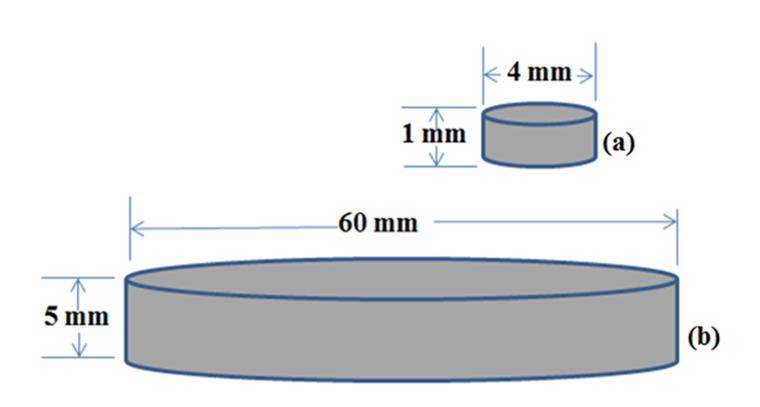

In this experiment, the pin along with disk specimens was made of SCM440 steel. The designation in both the SAE-AISI system for the pin material was 4140. The UNS number was G41400 and the EN numeric designation was 1.7225. From this material, cylindrical specimens were processed into dimensions according to the American Society for Testing and Materials (ASTM G99). Fig. 1 illustrates a schematic diagram of the pin and disk. The pin had a diameter of 4 millimetres and thickness urof 1 millimetre, whereas the disk was 5 millimetres thick and 60 millimetres in diameter. Rough edges were removed from the specimen surfaces and flat faces were achieved.

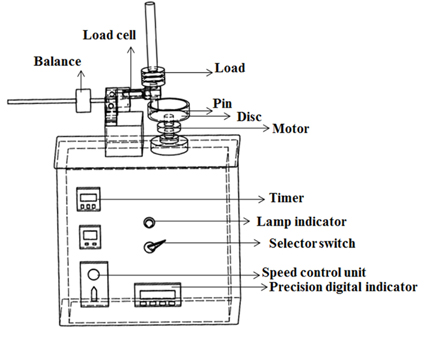

This research employed pin on disk tribotester in the examining the lubricants’ physical attributes as demonstrated in Fig. 2. Pin on disk tribotester was operated according to the ASTM G99 standard. The instrument is made up of a flat pin which was connected to a firm elastic arm weighted down onto a test specimen with an accurately measured weight. The specimen was rotated at a chosen speed. The elastic arm guaranteed an approximately fixed contact spot and a steady position in the friction track created by the pin on the specimen. The kinetic coefficient of friction was established in the course of the experiment through direct assessment of the changes in torque by means of a sensor positioned at the pivot point of the arm.

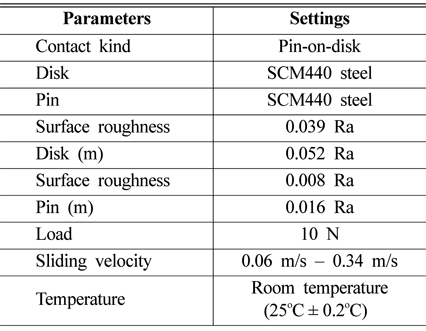

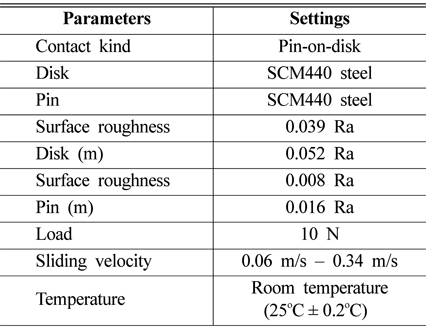

Components of the test machine included a pin gliding on the flat face of a disk turning in a vertical plane, with provisions to monitor the speed, load and oil flux. The pin and disk were cleaned with acetone to eliminate dirt and then placed on the test machine plate. The examined oil was contained in a cup and it was entrained into the interaction region of the turning disk. Load was used along the core of the pin. These examinations were carried out with a maximum load (10 N) and different sliding speeds (0.06 m/s-0.34 m/s). The detailed experimental conditions are illustrated in Table 1.

[Table 1.] Conditions of friction analysis

Conditions of friction analysis

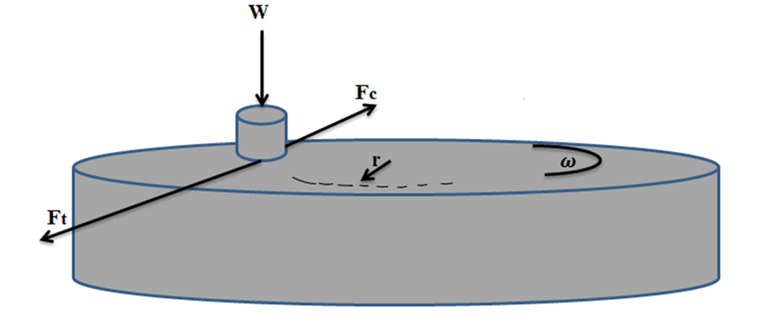

Fig. 3 demonstrates diagram of the path of forces during friction analysis. Load (W) is used over the pin while the disk turns at a fixed angular speed (

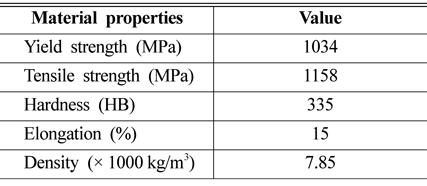

[Table 2.] Mechanical characteristics of pin and disk [15]

Mechanical characteristics of pin and disk [15]

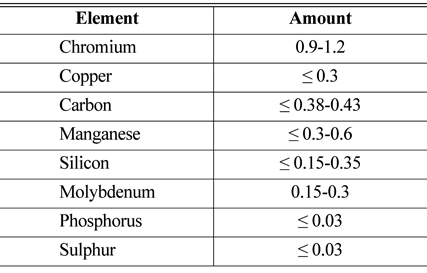

[Table 3.] Chemical combinations of pin and disk [15]

Chemical combinations of pin and disk [15]

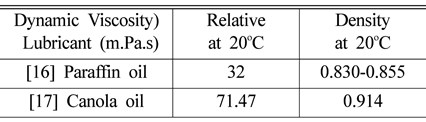

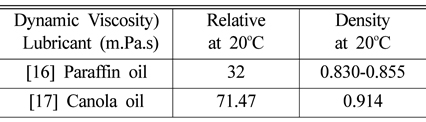

[Table 4.] Characteristics of lubricants

Characteristics of lubricants

Viscosity is quite an essential parameter for a lube because it influences the layer thickness and thus the amount of wear of the gliding surface. Viscosity is used for the designation of particular classes of oil as well as to monitor alterations that take place within the oil during the operation period. Elevated viscosity generally indicates that the oil has degenerated through oxidation while reduced viscosity typically suggests adulteration of the oil[3]. In this study, canola oil was investigated as a possible substitute lubricant oil. In comparison, a very highly refined mineral oil was also utilized for this experiment.

The dynamic viscosity of oils was estimated using a rotary viscometer (Brookfield, LVDV1) according to ASTM D4878. All measurements were taken at room temperature (25°C ± 0.2°C). The viscometer has a spindle that turns with a defined speed, and a torque which increases up to a peak value followed by a gradual decline until it reaches an equilibrium level. The viscosity can be measured in millipascal-second (mPa.s) as illustrated in Fig. 4. In this experiment, viscosity was measured in fresh state.

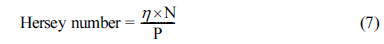

The condition of lubrication was examined using a Stribeck curve. It attests that friction within fluid-oiled interaction is not a sequential function of the lube viscosity, contact load as well as the lubricant entrainment velocity. The Stribeck curve demonstrates the connection between Hersey number, a dimensional lubrication parameter, and the coefficient of friction of two fluid-lubricated surfaces in contact. The Hersey number is given as:

Where

In boundary lubrication, the film thickness of lubricant is slimmer compared to the height of several asperities and there is also significant contact of roughness. It takes place at the time velocity is lowered or load is raised. The regime of mixed lubrication acts on reduced velocity, elevated temperature or further load which considerably lessens viscosity of lubricant. In this state, irregularities of the engaging faces at certain regions will sporadically interact. Hydrodynamic mechanism is the state in which the interaction load between the gliding faces is completely aided by moderately dense layer within them. Here, metal to metal interaction is prevented causing the coefficient of friction only to depend on the viscosity of the lubricant (at a steady load and speed)[18].

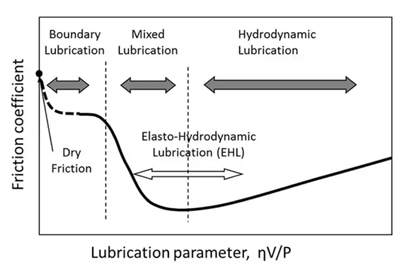

3-1. Viscosity of canola oil and paraffin oil

Fig. 6 shows the dynamic viscosity of both lubricants assessed at room temperature (25°C ± 0.2°C). The viscosity of canola oil was higher than that of paraffin oil. Canola oil demonstrated a viscosity of 46.67 mPa.s, whereas paraffin oil had a lower viscosity of 16.07 mPa.s., Generally, viscosity of the two oils decreased as temperature elevated. This result is in line with available literature which states that temperature has an impact on the viscosity of fluid materials with viscosity decreasing as temperature increases[19].

3-2. Comparative friction analysis of canola oil and paraffin oil

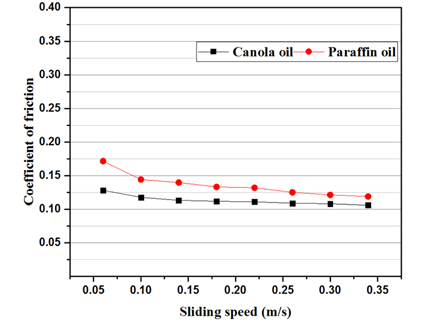

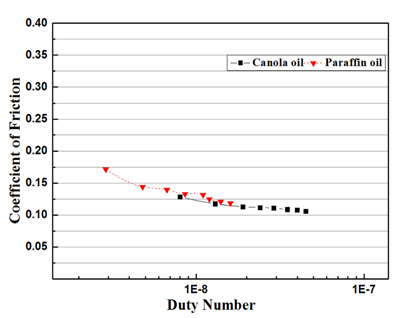

Coefficient of friction (

Fig. 7 illustrates the comparison of coefficient of friction for canola oil and paraffin oil in 40 minutes in a similar environment. In an adulterated condition, canola oil presentation was observed to be competitive in coefficient of friction with paraffin oil. It appeared that the lowest coefficient of friction was found in canola oil. This result is similar to a previous study which documented that friction coefficient of fatty acids is generally lower than that of mineral oil[13]. It is evident, from our study, that coefficient of friction for canola oil (µ = 0.10586) is lower than paraffin oil (µ = 0.11869)

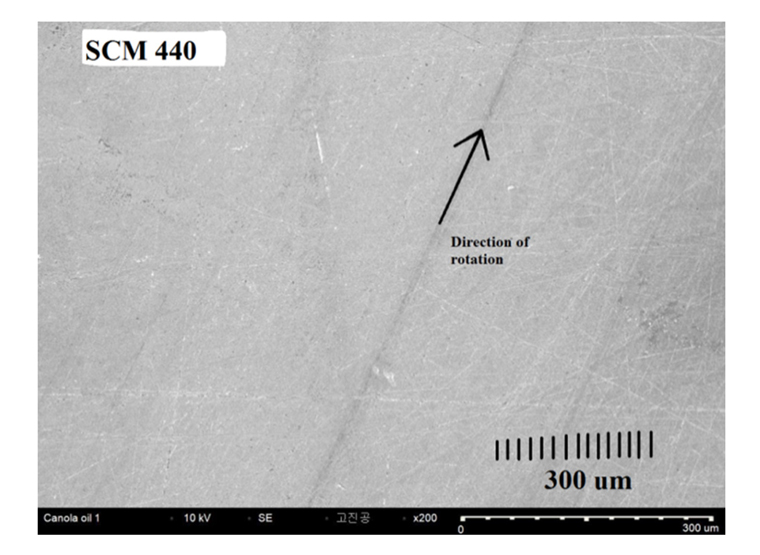

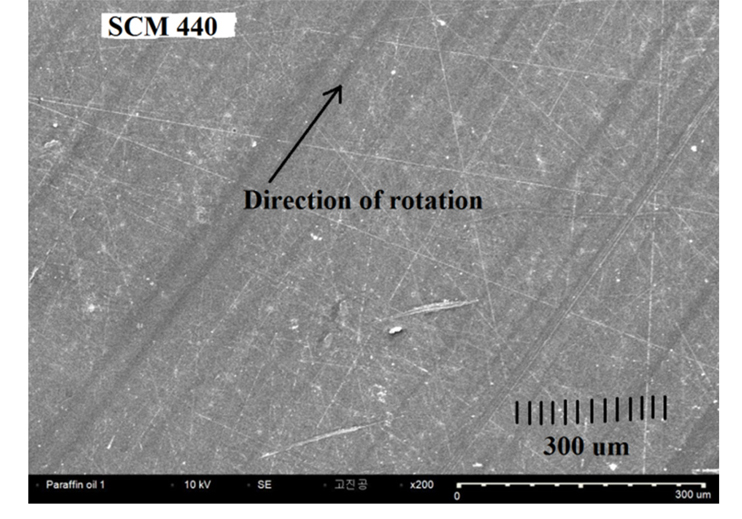

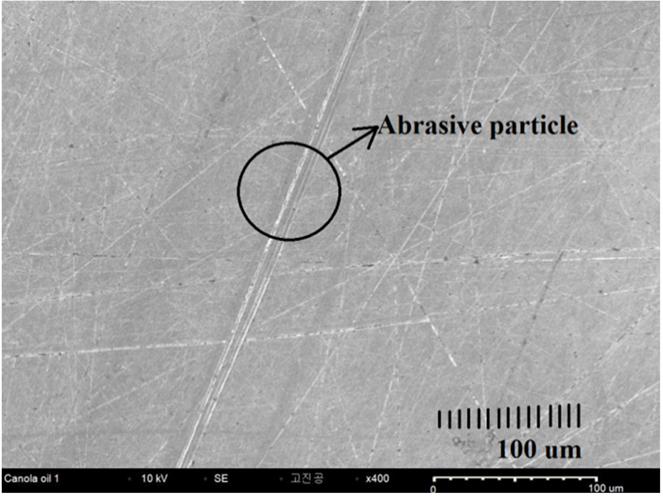

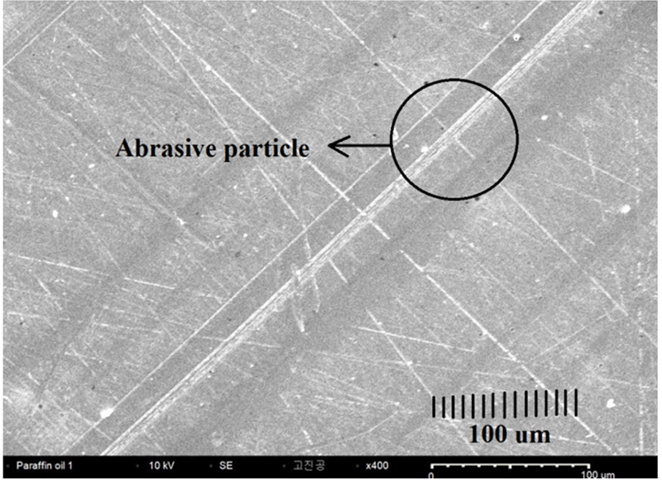

The images of SCM 440 surfaces are demonstrated in Fig. 8 and 9.

The abrasion occurred as a result of scrape practices on the SCM 440 surface during rotation. Marks that were created in the course of the experiment using canola oil appeared sleeker compared to those observed with paraffin oil. This also indicates that the canola oil is effective in minimizing the abrasions of materials at severe contact conditions. Images of the abraded surfaces were obtained following the experiment using scanning electron microscopy under ×28, ×200 and ×400 magnifications and acceleration voltage of 10 kV. According to the results (Fig. 7), it can be deduced that canola oil was considerably more effective in friction reduction compared to paraffin oil. Fig. 10 and 11 evidently supported this observation. The abraded surface of SCM 440 with canola oil lubrication appeared to have less damage compared to the alternative treatment.

According to the results obtained as shown in Fig. 12, it can be deduced that canola oil demonstrated considerably more effective elasto-hydrodynamic film-forming properties compared to paraffin oil, mostly at room temperature. This improved lubricity of canola oil can be explained by its fatty acid composition. Our finding aligns with previous literature which states that fatty acids contain carboxyl set in its series that is attracted to the metal surface because of its polarity[11]. This process incorporates intermolecular forces like Van der Waals and is also capable of giving a single-molecular film to reduce friction over the surface.

This study compared a natural vegetable oil against an extremely refined mineral oil. Interestingly, the canola oil possesses more effective characteristics which are crucial for its use in industrial operations. From the above investigations, it can be concluded that at a greater applied load and elevated sliding velocity, the coefficient of friction of SCM 440 lubricated with canola oil resulted in smaller values of coefficient of friction compared with lubrication with paraffin oil. Canola oil as a base lubricant in comparison with paraffin oil has more efficient anti-friction characteristics. Canola oil possesses a better viscosity than paraffin oil. The non-dimensional characteristic number from the Stribeck curve revealed an elasto-hydrodynamic lubrication regime with canola oil lubrication. Following the friction operation, the microstructures sustained scratches under the both environments. The SCM 440 surface lubricated with paraffin oil demonstrated a thick track which revealed extreme abrasion compared to that seen with the canola oil treatment.

![Mechanical characteristics of pin and disk [15]](http://oak.go.kr/repository/journal/22450/OHHHB9_2020_v36n1_11_t002.jpg)

![Chemical combinations of pin and disk [15]](http://oak.go.kr/repository/journal/22450/OHHHB9_2020_v36n1_11_t003.jpg)